An investor’s total cost for a hot-dip galvanizing plant falls into three main categories. These are Capital Equipment, Infrastructure, and Operations. The price of hot-dip galvanizing equipment includes key items. These items are the galvanizing kettle, pre-treatment tanks, and material handling systems. Infrastructure costs cover land, building, and utility setup. Operational costs are ongoing expenses for raw materials, energy, and labor.

The hot-dip galvanizing market shows strong growth potential. This growth is driven by infrastructure investments and demand for corrosion-resistant materials. The market for products like pipes galvanizing lines is expanding.

| Metric | Value |

|---|---|

| Market Size in 2024 | USD 62.39 Billion |

| Market Size in 2032 | USD 92.59 Billion |

| CAGR (2025-2032) | 6.15% |

Key Takeaways

- Setting up a galvanizing plant costs money for equipment, land, and buildings. The main equipment includes the galvanizing kettle and machines to move steel.

- Running a galvanizing plant has ongoing costs. These include buying zinc, paying for energy, and paying workers.

- The price of zinc changes often. This change affects how much it costs to run the plant every day.

Initial Investment: The Price of Hot-Dip Galvanizing Equipment and Infrastructure

The initial investment represents the most significant financial hurdle when establishing a galvanizing plant. This phase includes all upfront expenditures on equipment, physical structures, and setup. The total cost varies widely based on the plant’s intended capacity, level of automation, and geographic location. A basic plant for small-batch items might start around $20,000. A large-scale, continuous processing line can exceed $5,000,000.

A sample investment breakdown for a mid-sized plant illustrates the distribution of costs.

| Category | Cost (INR Lakh) |

|---|---|

| Land & Infrastructure | 50 – 75 |

| Machinery & Equipment | 120 – 200 |

| Zinc Inventory | 15 – 30 |

| Labor & Utilities | 10 – 15 |

| Licensing & Compliance | 5 – 10 |

| Total Initial Investment | 200 – 300 |

Galvanizing Kettle: Size and Material

The galvanizing kettle is the heart of the operation and a primary cost driver. Its dimensions—length, width, and depth—determine the maximum size of steel products the plant can process. A larger kettle holds more molten zinc, requiring more energy to heat and increasing the overall price of hot-dip galvanizing equipment. Kettles are typically made from special low-carbon, low-silicon steel to resist corrosion from molten zinc. The material quality directly influences the kettle’s lifespan and replacement frequency.

Pre-Treatment Tanks

Before galvanizing, steel must undergo a series of cleaning steps. This process occurs in pre-treatment tanks. The number and size of these tanks depend on the desired throughput and the condition of the incoming steel. A typical pre-treatment line includes several stages:

- Degreasing: Removes oil, dirt, and grease.

- Rinsing: Washes away degreasing chemicals.

- Pickling: Uses acid (like hydrochloric acid) to remove mill scale and rust.

- Rinsing: Washes away the acid.

- Fluxing: Applies a zinc ammonium chloride solution to prevent re-oxidation before dipping.

These tanks are often constructed from materials like polypropylene or fiber-reinforced plastic (FRP) to withstand corrosive chemicals.

Material Handling Systems

Efficient material handling is crucial for productivity and safety. These systems transport steel through every stage of the process. The choice between manual, semi-automatic, and fully automatic systems significantly impacts the initial investment.

| System Type | Average Price Range (USD) |

|---|---|

| Semi-Automatic Line | $30,000 – $150,000 |

| Fully Automatic Line | $180,000 – $500,000 |

| Custom Turnkey Plant | $500,000+ |

Note: Manual handling has a lower upfront cost but often leads to higher long-term expenses. These expenses come from workplace accidents, product damage, and slower production. Automated systems require a larger initial investment and skilled operators. However, they deliver greater cost-effectiveness over time through increased efficiency and a safer work environment. The price of hot-dip galvanizing equipment rises with automation, but so does the plant’s long-term profitability.

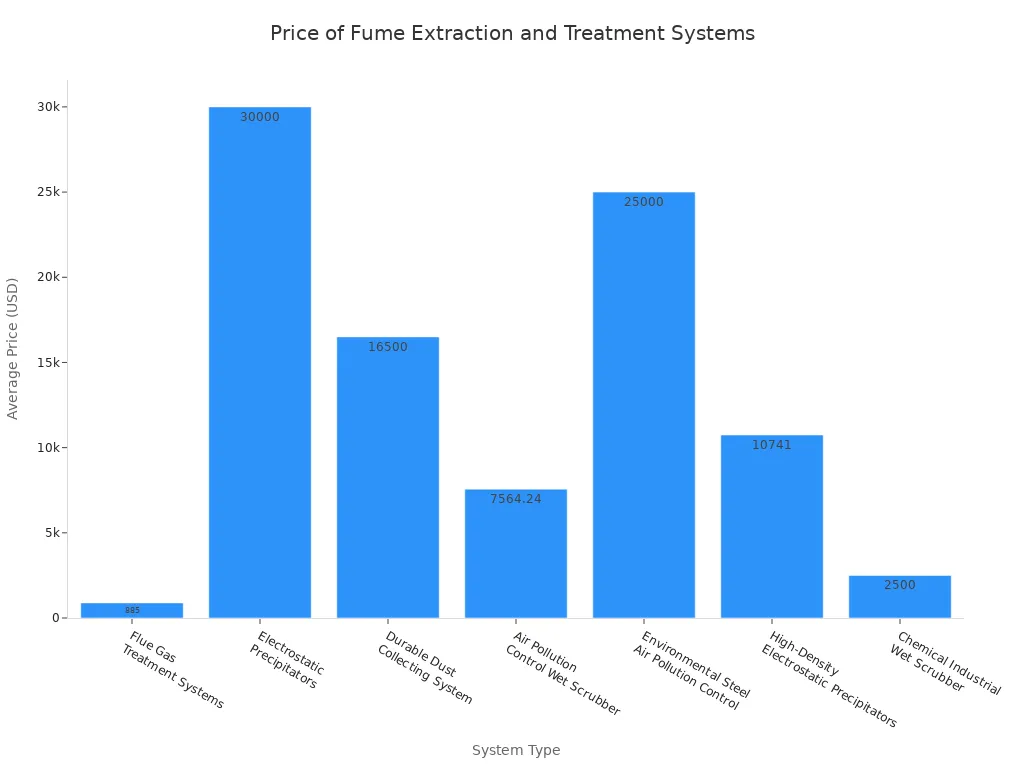

Heating and Fume Treatment Systems

The galvanizing kettle requires a powerful heating system to keep the zinc molten at approximately 840°F (450°C). High-velocity natural gas burners are a common choice. Just as important is the fume treatment system. The galvanizing process generates hazardous fumes and dust that require capture and treatment to meet environmental regulations.

Compliance with standards from the Environmental Protection Agency (EPA) or the European Union (EU) is non-negotiable. In North America, 70% of manufacturing firms prioritize upgrading filtration systems to meet air quality standards. Businesses show a willingness to pay a 10-15% premium for systems that guarantee compliance and offer superior filtration. This makes the fume treatment system a critical part of the budget.

Land and Building

The cost of land and construction depends heavily on the plant’s location. A galvanizing plant requires a significant footprint to accommodate the entire production line, from steel arrival to finished product storage. The building itself has specific design needs. It must have high ceilings to operate overhead cranes and robust foundations to support heavy equipment like the kettle. Proper ventilation infrastructure is also essential to manage heat and air quality throughout the facility. These factors make industrial-zoned land and specialized construction a major part of the initial capital outlay.

Utilities and Installation

A galvanizing plant is a major consumer of energy, primarily natural gas and electricity. Setting up high-capacity utility connections is a substantial one-time cost. Natural gas line installation costs vary based on several factors:

- Distance from the main gas supply

- Complexity of the trenching and installation

- Type of pipe material used (e.g., steel, HDPE)

Installation costs for a new gas line can range from $16 to $33 per linear foot. A new line running from the street to the facility can easily exceed $2,600, with complex industrial projects costing much more. Similarly, establishing a high-capacity electrical connection for motors, cranes, and controls requires coordination with local utility providers and can be a complex, costly process. The installation of all machinery is the final component that contributes to the total price of hot-dip galvanizing equipment.

Ongoing Operational Costs

After the initial setup, a galvanizing plant‘s financial health depends on managing its ongoing operational costs. These recurring expenses directly influence the price of the final galvanized product and the plant’s overall profitability. Careful management of raw materials, energy, labor, and maintenance is essential for long-term success.

Raw Materials: Zinc and Chemicals

Raw materials represent the largest portion of a plant’s operational budget. Zinc is the most critical and costly component. The price of Special High Grade (SHG) zinc fluctuates based on global supply and demand, making it a variable expense that plant managers must monitor closely. Market indexes, such as the ‘Zinc special high grade in-warehouse Rotterdam premium’ provided by Argus Metals, offer a benchmark for pricing.

The cost of zinc can vary significantly between suppliers and regions.

| Product Description | Purity | Price Range (USD/ton) |

|---|---|---|

| Special High Grade Zinc Ingot | 99.995% | $2,900 – $3,000 |

| High Grade Zinc Ingot | 99.99% | $2,300 – $2,800 |

| Standard Zinc Ingot | 99.5% | $1,600 – $2,100 |

Note: The prices above are illustrative and fluctuate daily. A plant owner must establish reliable supply chains to secure competitive pricing.

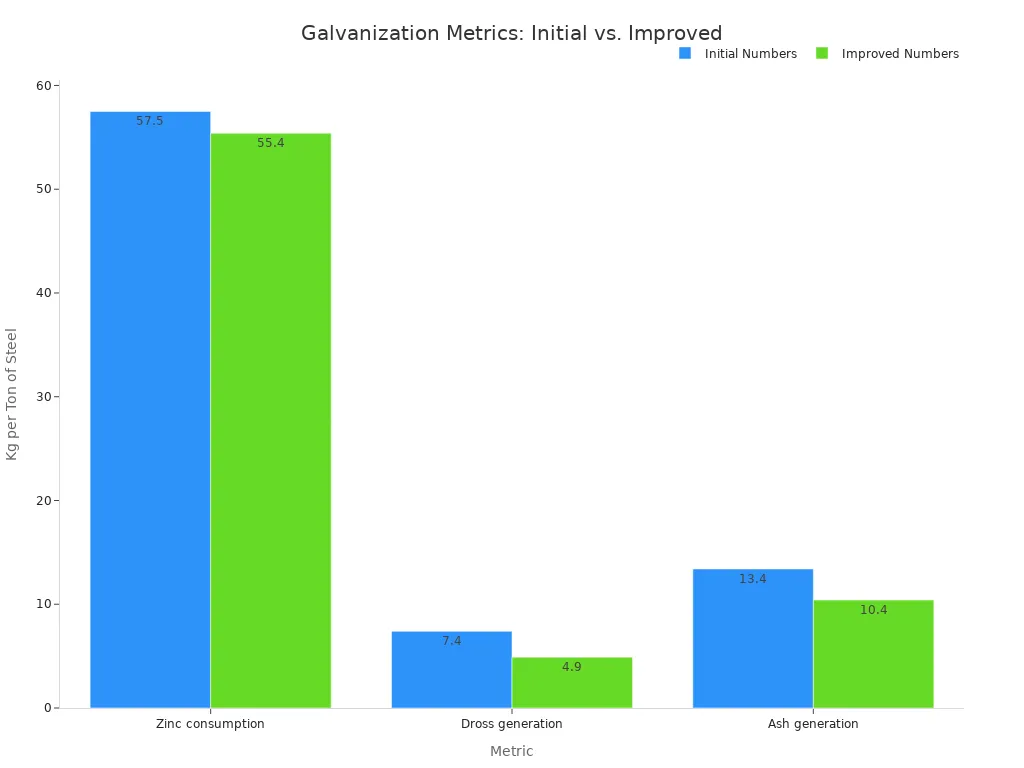

A plant’s zinc consumption includes more than just the coating on the steel. The process also creates byproducts like zinc dross (an iron-zinc alloy) and zinc ash (zinc oxide). These byproducts represent a loss of usable zinc. However, process improvements can significantly reduce this waste. Efficient operations lead to lower consumption and less byproduct generation, directly cutting material costs.

Other essential raw materials include the chemicals for the pre-treatment process. These are:

- Degreasing agents to clean the steel.

- Hydrochloric or sulfuric acid for pickling.

- Zinc ammonium chloride for the flux solution.

The cost of these chemicals, along with their safe storage and disposal, adds to the total operational expense.

Energy Consumption

Galvanizing plants are energy-intensive operations. The two primary energy expenses are natural gas and electricity.

- Natural Gas: The furnace system consumes large amounts of natural gas to keep hundreds of tons of zinc molten at 840°F (450°C) around the clock.

- Electricity: High-wattage motors power the overhead cranes, pumps, and fume extraction fans.

Investing in energy-efficient technology can dramatically lower these costs. Modern furnace designs, for example, can reduce annual energy needs by over 20%. An improved system might lower energy use from 399.3 MJ/tonne of steel to just 307 MJ/tonne. This 23% drop in consumption translates directly into significant financial savings and a smaller carbon footprint, making energy optimization a key goal for any modern plant.

Labor and Training

A skilled and efficient workforce is the engine of a galvanizing plant. Labor costs are a major operational expense and vary based on geographic location and local wage laws. Key roles in a plant include:

- Crane operators

- Workers for jigging (hanging) and de-jigging steel

- Kettle operators or “dippers”

- Fettlers (for finishing)

- Quality control inspectors

- Maintenance technicians

Proper training is not an expense but an investment. A well-trained team works more safely and efficiently. This reduces workplace accidents, minimizes damage to customer products, and ensures consistent quality. Ongoing training programs help employees stay updated on best practices for safety, environmental compliance, and operational efficiency, ultimately boosting the plant’s productivity and reputation.

Maintenance and Spare Parts

Mechanical equipment operating in a harsh, high-temperature environment requires constant attention. A proactive maintenance schedule is crucial to prevent unexpected breakdowns and costly production stoppages.

Pro Tip: A planned maintenance program costs less than emergency repairs. Scheduling regular inspections for the kettle, cranes, and fume system ensures reliability and extends the life of expensive equipment.

Key maintenance activities include furnace upkeep, crane inspection, and cleaning of the fume treatment system. A plant must also budget for a stock of essential spare parts. Common spare parts include:

- Burners and thermocouples for the furnace

- Pump seals and impellers

- Filters for the fume extraction system

- Electrical components like contactors and relays

Having these parts on hand allows for quick repairs, minimizing downtime and keeping the production line moving.

Kettle size, infrastructure, and zinc prices are the primary cost drivers. A plant’s capacity, automation, and location determine the final investment. The price of hot-dip galvanizing equipment varies widely. Investors should consider the payback timeline during planning.

- A new plant’s expected payback period should be 5 years or less.

Tip: For an accurate estimate, consult with plant manufacturers to receive a detailed, customized quote.

Post time: Dec-02-2025