Persistent delays often challenge galvanizing operations. Crane wait times, inconsistent cleaning of galvanizing baths, and process bottlenecks are common issues. Targeted automation directly solves these problems. Implementing specific solutions like advanced Materials Handling Equipment boosts throughput, cuts operational costs, and significantly improves worker safety around the plant.

Key Takeaways

- Automation fixes common delays in galvanizing plants. It makes crane operations faster and more precise.

- Automated tools keep the zinc bath clean. This improves product quality and makes the process safer for workers.

- Automatic systems move materials smoothly between steps. This stops bottlenecks and makes the whole production line work better.

Inefficient Crane Operation and Manual Handling

The Problem: Manual Crane Delays and Safety Risks

Manual cranes are a frequent source of production delays in galvanizing plants. Operations depend entirely on the availability and skill of a human operator. This reliance introduces variability and wait times, as jigs and materials queue for their turn to be lifted and moved. Manual systems have inherent limitations in speed and precision, which often create significant production bottlenecks.

Did You Know? Each minute a production line waits for a crane is a minute of lost throughput, directly impacting profitability and delivery schedules.

These delays are not just an efficiency problem; they also pose safety risks. Manual handling of heavy, hot, or chemically-treated materials increases the potential for accidents and operator error. Optimizing this stage is critical for creating a safer and more productive workflow, which starts with better Materials Handling Equipment.

The Solution: Automated Crane and Hoist Systems

Automated crane and hoist systems provide a direct and effective solution. These systems automate repetitive lifting tasks, accelerating cycle times and reducing the downtime associated with manual operations. Electric hoists integrated with overhead cranes form the core of a modern production line, moving components with a speed and endurance that manual systems cannot match. This automation is essential for high-volume, repetitive lifting where consistency is critical.

Modern automated cranes are engineered for the demanding galvanizing environment. They offer precise, programmable control over every movement.

| Parameter | Typical Value |

|---|---|

| Load Capacity | 5 to 16 tons (customizable) |

| Hoist Lifting Speed | Up to 6 m/min (variable) |

| Crane Travel Speed | Up to 40 m/min (variable) |

| Control System | PLC-based with remote operation |

| Safety Features | Collision avoidance, load monitoring |

By integrating this technology, plants can optimize their entire workflow. Automated cranes work seamlessly with other Materials Handling Equipment to ensure a smooth transition between processes. This upgrade boosts productivity, enhances safety by removing workers from hazardous areas, and makes the entire line of Materials Handling Equipment more efficient.

Inconsistent Kettle Cleaning and Zinc Waste

The Problem: Manual Drossing and Skimming Inefficiencies

Manual kettle maintenance is a major source of process variability and waste. Ineffective drossing allows zinc-iron compounds to contaminate the final product, harming its finish. Similarly, if workers do not properly remove zinc skimmings (oxidized zinc) from the bath’s surface, these deposits can settle on the steel during withdrawal. This inefficient skimming allows oxides to become trapped within the galvanized coating, creating irregularities that negatively impact the product’s visual quality.

Beyond product quality, manual drossing takes a significant physical toll on workers. The process exposes them to numerous safety hazards.

Common Manual Drossing Risks

- Musculoskeletal strains in the lower back and arms from lifting heavy tools.

- Confirmed cases of carpal tunnel syndrome and wrist injuries.

- Constant exposure to extreme heat from the molten zinc.

- Awkward shoulder and trunk postures that increase physical load.

This combination of inconsistent results and safety risks makes manual kettle cleaning a prime target for automation.

The Solution: Robotic Drossing and Skimming Tools

Robotic drossing and skimming tools provide a precise and reliable alternative. These automated systems operate with unmatched consistency, directly improving the galvanizing process. Their controlled movements remove dross and skim the bath surface without creating unnecessary turbulence in the molten zinc. This leads to a cleaner, more stable kettle environment.

Automated systems use advanced technology like machine vision to identify and remove slag efficiently. This optimization reduces zinc and power consumption by eliminating unnecessary cleaning cycles. The benefits are clear:

- They ensure clean baths, preventing localized “hot spots” for uniform immersion.

- They perform dross removal with controlled, gentle movements.

- They operate on a consistent schedule, maintaining optimal zinc purity.

By automating this critical task, galvanizing plants reduce zinc waste, improve coating quality, and remove employees from a hazardous job.

Optimizing Workflow with Automated Materials Handling Equipment

The Problem: Pre-Treatment and Post-Treatment Bottlenecks

A galvanizing line’s efficiency often breaks down during transitions. The manual movement of materials between pre-treatment tanks, the galvanizing kettle, and post-treatment cooling stations creates significant bottlenecks. Jigs loaded with steel must wait for an available crane and operator, causing queues and idling equipment. This stop-and-go process disrupts the production rhythm, limits throughput, and makes it difficult to maintain a consistent processing time for each load. Each delay at these transfer points ripples through the entire line, reducing overall plant capacity and efficiency.

The Solution: Fully Automatic Transfer Systems

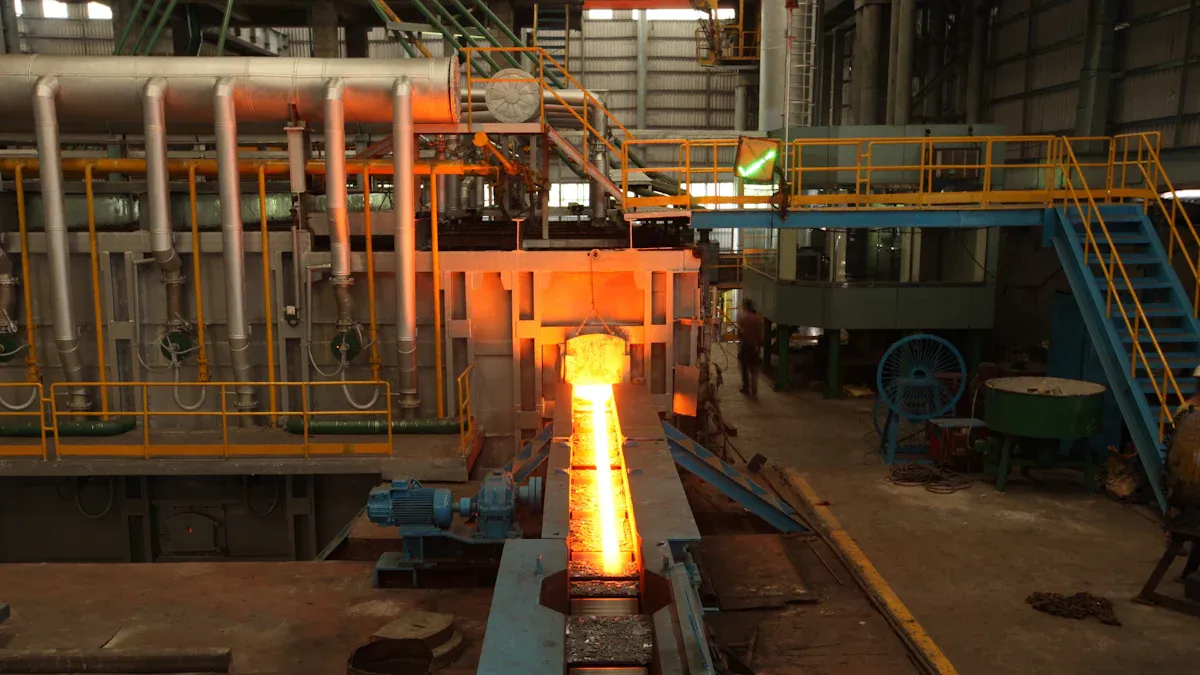

Fully automatic transfer systems provide a direct solution to these workflow disruptions. This state-of-the-art Materials Handling Equipment uses a combination of conveyor belts, rollers, and intelligent controls to automate and coordinate the movement of materials. These systems are engineered for seamless integration with existing plant infrastructure, connecting stages like heating furnaces, galvanizing baths, and cooling equipment. A typical setup includes a conveyor belt with positioning rods to secure items and a cooling box for efficient air and water cooling of steel parts.

By automating the entire transfer process, these systems eliminate manual intervention and the associated delays. Intelligent sensors and control systems ensure automatic starting, stopping, and precise positioning for a smooth and continuous workflow. This level of control improves the consistency and stability of the entire process.

Enhanced Process Control Advanced control systems like Programmable Logic Controllers (PLCs) and manufacturing execution systems (MES) provide complete line supervision. They manage working recipes and offer full traceability from raw material to finished product.

This integration of smart controls with robust Materials Handling Equipment maximizes process performance, boosts production efficiency, and creates a safer, more predictable operating environment.

Automation effectively eliminates recurring delays from manual handling and process transitions. Automated cranes and robotic tools are proven solutions that enhance safety. They also boost production, with data showing automation improves throughput by 10% in many facilities. Evaluating a line’s specific bottlenecks identifies where a targeted strategy delivers the highest return.

Post time: Dec-15-2025