You can boost your production efficiency with pretreatment drum heating. Preparing raw materials before manufacturing helps you speed up processes, maintain quality, and save on costs. The Pretreatment Drum & Heating system uses smart features that set it apart. For example, you benefit from waste heat recovery, advanced heating mechanisms, and precise temperature control. Take a look at some innovative features found in today’s systems:

| Feature | Description |

|---|---|

| Integrated inline dephosphating systems | Chemical removal of phosphate coatings for better fastener quality. |

| Soft handling techniques | Gentle processing to avoid damaging products. |

| Sophisticated metering systems | Accurate control of wash solutions and process settings. |

| Improved temperature uniformity | Even heating for consistent product results. |

Consider how these solutions can fit into your own production line for better outcomes.

Key Takeaways

- Pretreatment drum heating speeds up production by heating and moving materials simultaneously, reducing cleaning and drying times.

- Consistent heating ensures uniform material quality, which is crucial for industries like pharmaceuticals and food processing.

- The waste heat recovery system lowers energy costs by recycling heat, making operations more sustainable and cost-effective.

- Regular maintenance and monitoring of the system enhance reliability and extend equipment life, preventing costly breakdowns.

- Adjusting temperature settings and using sensors can optimize performance, leading to better product quality and lower operating costs.

Faster Processing

You can speed up your production line with pretreatment drum heating. The system uses a rotating barrel and advanced heating to treat raw materials quickly. In chemical manufacturing, you often need to remove rust or grease before the next step. The drum heats and moves the materials at the same time. This process shortens the time needed for cleaning and drying. Food processing plants also benefit from faster drying and preparation. You get more products ready in less time.

Tip: When you use pretreatment drum heating, you can reduce bottlenecks and keep your workflow moving smoothly.

Consistent Material Quality

Pretreatment drum heating helps you achieve uniform results. The rotating barrel and heating system treat each batch of raw materials evenly. In pharmaceutical manufacturing, you must keep material properties consistent. This system changes the physical or chemical properties of the materials before they enter production. You get better handling and processing in later stages. Uniform treatment means every product meets strict quality standards. Food processors also rely on this consistency to avoid uneven cooking or drying. Chemical plants see fewer defects and more reliable results.

Lower Energy Costs

You can save money on energy with pretreatment drum heating. The system uses waste heat recovery to heat all pretreatment tanks. This feature captures flue gas and reuses it, which lowers your energy bills. Chemical factories often spend a lot on heating. By recycling heat, you use less fuel and cut costs. Food and pharmaceutical industries also benefit from this energy-saving design. The combined heat exchanger and PFA heat exchanger work together to keep temperatures steady without wasting power.

Industry Benefit from Pretreatment Drum Heating Chemical Faster cleaning, lower energy use Food Quicker drying, consistent quality Pharmaceutical Uniform material properties, energy savings Pretreatment drum heating gives you speed, quality, and savings. You can improve your production process and see better results in every batch.

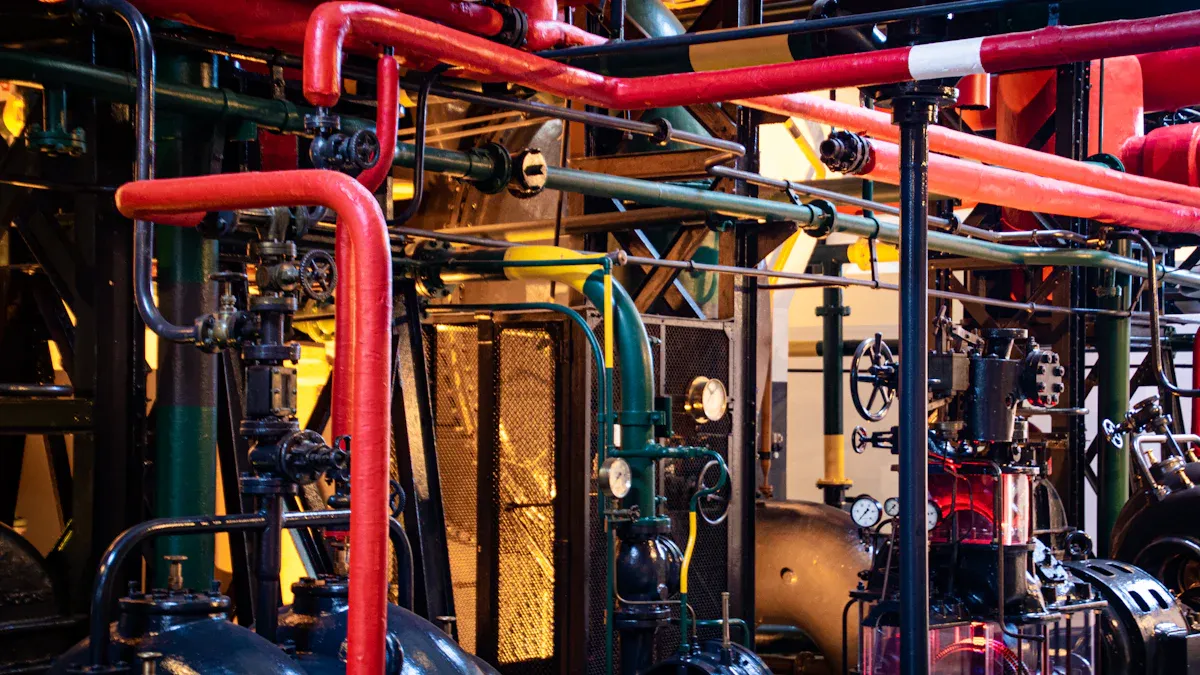

How Pretreatment Drum Heating Works

Efficiency Gains With Pretreatment Drum Heating

Rotating Barrel Technology

You see better results when you use rotating barrel technology in your production line. The barrel spins along a horizontal axis. This movement keeps the materials inside in constant motion. The tumbling action helps every particle get the same amount of heat. You avoid hot and cold spots because the barrel never lets the material sit still. New surfaces touch the heat source all the time. This process stops temperature gradients from forming. You get uniform heating and consistent quality in every batch.

- The barrel rotates and agitates the material.

- Every particle receives equal exposure to heat.

- The constant movement prevents uneven temperatures.

Note: Uniform heating means you can trust the quality of your finished products.

Advanced Heating Mechanisms

You benefit from advanced heating mechanisms in pretreatment drum heating systems. These systems use a combination of heat exchangers to reach the right temperature quickly. The combined heat exchanger and PFA heat exchanger work together. You get precise control over the heating process. The system keeps the temperature steady, so you do not have to worry about overheating or underheating. You can adjust the settings to match the needs of different materials. This flexibility helps you prepare raw materials for many types of manufacturing.

| Heating Feature | Benefit |

|---|---|

| Combined heat exchanger | Fast and efficient heating |

| PFA heat exchanger | Accurate temperature control |

| Drying oven | Moisture prevention |

Waste Heat Recovery System

You save energy with the waste heat recovery system. The system captures flue gas from the heating process. It uses this waste heat to warm all pretreatment tanks. You lower your energy bills because you recycle heat instead of letting it escape. This design helps you run a more sustainable operation. You also keep the temperature stable across all tanks. The waste heat recovery system makes pretreatment drum heating more efficient and cost-effective.

Tip: Using waste heat recovery helps you meet energy-saving goals and reduce your carbon footprint.

Pretreatment drum heating combines smart movement, advanced heating, and energy-saving features. You get reliable results, lower costs, and better control over your production process.

Solving Production Challenges

Temperature Control

You need precise temperature control to get the best results in your production line. Pretreatment drum heating gives you the ability to set and maintain the right temperature for each batch. The system uses advanced sensors and heat exchangers. These tools help you avoid overheating or underheating. You can adjust the temperature for different materials. This control helps you protect sensitive products and improve overall quality.

Tip: Regularly check your temperature settings to make sure you meet your process requirements.

Material Preparation (Degreasing, Rust Removal, Drying)

You want your raw materials clean and ready for the next step. Pretreatment drum heating helps you prepare materials with proven methods. You can follow these best practices:

- Pre-cleaning: Soak the substrate in a cleaning agent. This step removes bulk contaminants.

- Secondary cleaning: Polish the surface to eliminate microscopic soil traces. You can use abrasive blasting or ultrasonic washing.

- Pickling: Remove rust and impurities from metals using acidic solutions.

You get a thorough cleaning process. Each step prepares your materials for further manufacturing. You see fewer defects and better product performance.

| Step | Purpose |

|---|---|

| Pre-cleaning | Removes bulk contaminants |

| Secondary cleaning | Eliminates microscopic soil |

| Pickling | Removes rust and impurities |

Moisture Prevention

You must keep moisture away from your materials to prevent problems during production. The drying oven in the system helps you achieve this goal. You dry materials after cleaning and rust removal. This step stops moisture from causing corrosion or affecting coatings. You get better adhesion and longer-lasting products.

Note: Dry materials help you avoid costly rework and ensure high-quality results.

Pretreatment drum heating helps you solve common production challenges. You control temperature, prepare materials, and prevent moisture issues. You improve your workflow and get reliable results every time.

Implementation Steps

You can add pretreatment drum heating to your workflow by following clear steps. First, assess your current production line. Identify where raw materials need cleaning, drying, or heating. Next, select the right drum size and heating capacity for your materials. Work with your team to plan the installation. Make sure you have space for the rotating barrel and heating units. Connect the system to your existing controls. Test the equipment before starting full production. Train your operators to use the new system safely and efficiently.

Tip: Start with a pilot run to check how the system fits with your process.

Maintenance Advice

Regular maintenance keeps your equipment running smoothly. You should set up daily and periodic checks. Operators can look for leaks, unusual noises, or temperature changes. Schedule professional inspections to catch problems early. A planned maintenance program helps you avoid breakdowns and save on fuel costs. Focus on key parts like conveyors, spray pumps, pump screens, risers, spray nozzles, float valves, oil skimmers, feed pumps, controllers, ventilation systems, and heat exchangers. Make sure each part works as it should. Follow the manufacturer’s schedule for overhauls.

- Check all moving parts daily.

- Inspect spray nozzles and pumps weekly.

- Clean screens and filters regularly.

- Verify heat exchangers and ventilation systems monthly.

- Schedule full system inspections as recommended.

Note: Good maintenance leads to longer equipment life and higher reliability.

Optimization Strategies

You can maximize efficiency by fine-tuning your system. Adjust temperature settings for different materials. Monitor energy use and look for ways to improve heat recovery. Use sensors to track performance and spot issues early. Review production data to find bottlenecks. Train staff to handle the system correctly. Update your maintenance plan as your needs change. Keep spare parts on hand for quick repairs.

| Strategy | Benefit |

|---|---|

| Adjust temperature | Better material quality |

| Monitor energy use | Lower operating costs |

| Use sensors | Early problem detection |

| Train staff | Safer operation |

Pretreatment drum heating works best when you follow smart steps, keep up with maintenance, and look for ways to improve. You can boost your production and keep your system running at its best.

You can transform your production line with pretreatment drum heating. This technology helps you solve challenges like energy consumption and material consistency. You get uniform heat, lower costs, and easy setup.

- Full insulation reduces waste and keeps temperatures steady.

- Adjustable heaters fit many container sizes for versatile use.

Explore these resources to guide your next steps:

| Advantage | Description |

|---|---|

| Time and cost efficiency | Shortens processing times and boosts productivity. |

| Improved product quality | Delivers consistent results and builds confidence. |

| Improved safety measures | Adds temperature monitoring for safer operation. |

| Versatility | Adapts to different materials and industries. |

Stay updated on new trends like smart controls and better energy efficiency. You can meet industry standards and improve your workflow.

FAQ

Integration Tips

How does pretreatment drum heating improve production speed?

You speed up your workflow because the rotating barrel heats and moves materials at the same time. This process reduces waiting times for cleaning and drying. You can process more batches in less time.

Can you use pretreatment drum heating for different materials?

You can adjust the system for metals, plastics, and food products. The advanced heating controls let you set the right temperature for each material. You get reliable results across many industries.

What maintenance does the system require?

You should check moving parts daily and inspect heat exchangers monthly. Clean filters and screens regularly. Schedule full system inspections as recommended. Good maintenance helps you avoid breakdowns and keeps your system running smoothly.

Does the system help lower energy costs?

Yes! The waste heat recovery system captures flue gas and reuses it to heat pretreatment tanks. You use less fuel and save money on energy bills.

Is pretreatment drum heating safe for operators?

You get safer operation with temperature monitoring and automated controls. The system reduces manual handling and lowers the risk of accidents. Training your staff helps ensure safe and efficient use.

Post time: Jan-12-2026