You face many challenges with waste in metal smelting. The flux recycling unit changes how you manage this waste by turning scrap and slag into reusable materials. This advanced system uses collection, separation, and closed-loop technology to cut down on waste and save money. The unit also recovers energy, which lowers your costs and supports your sustainability goals.

| Innovation Description | Impact on Waste Management |

|---|---|

| Reprocessing scrap into flux or auxiliary materials | Minimizes waste and reduces environmental impact of metal production |

| Collection and separation of waste residue | Prepares materials for regeneration, ensuring quality for reuse |

| Closed-loop system with treatment and monitoring | Reduces waste generation and provides sustainable flux sources |

| Cost savings through material reuse | Lowers production costs and reliance on raw materials |

| Compliance with environmental regulations | Enhances reputation and aligns with sustainability goals |

Key Takeaways

- The flux recycling unit transforms waste into reusable materials, reducing landfill waste and supporting sustainability.

- Implementing this system can lead to significant cost savings by lowering the need for new materials and reducing waste disposal fees.

- Energy recovery features in the unit capture waste heat, enhancing energy efficiency and lowering operational costs.

- Using advanced recycling technology helps companies comply with environmental regulations and improve their public image.

- Many factories report quick returns on investment, with noticeable improvements in safety and efficiency within the first year.

Waste Problems in Metal Smelting

Types of Waste

You encounter many types of waste during metal smelting. These wastes include heavy metals and chemical byproducts. Some of the most common metals found in smelting waste are:

- Lead

- Zinc

- Nickel

- Copper

- Cadmium

- Chromium

- Mercury

- Selenium

- Arsenic

- Cobalt

Different smelters produce unique waste. For example, aluminum smelters release fluoride, benzo(a)pyrene, antimony, and nickel. Copper smelters create cadmium, lead, zinc, arsenic, and nickel. Lead smelters generate antimony, asbestos, cadmium, copper, and zinc. You must handle each type of waste carefully to protect people and the environment.

Environmental and Cost Impact

Waste from metal smelting can harm the environment. If you do not treat waste properly, it can contaminate soil and water. Toxic substances may leak into the ground, affecting plants and soil animals. Water pollution can damage fish and other aquatic life. Airborne pollutants from smelting can irritate your eyes, nose, and throat. Long-term exposure may cause heart and lung problems or even lead to serious diseases.

Managing waste also costs money. General waste management can cost you $500 to $5,000 each year, depending on how much waste you produce and recycle. Hazardous waste costs more, ranging from $2,000 to $50,000 annually. Disposal fees for hazardous waste can reach $200 or more per ton. These costs add up quickly for your facility.

Tip: Using advanced solutions like the flux recycling unit can help you lower these costs and reduce environmental risks.

Traditional Management Limits

Traditional waste management methods have several limits. You may face these challenges:

| Limitation | Description |

|---|---|

| Environmental Impact | Smelting produces air pollution, such as sulfur dioxide and carbon monoxide. It also creates slag and other waste that need careful handling. |

| High Energy Consumption | Smelting uses a lot of energy to reach high temperatures. This increases your costs and carbon emissions. |

| Complexity | You must control temperature, chemical reactions, and equipment maintenance. This makes the process difficult and time-consuming. |

You need better ways to manage waste and energy. New technology can help you overcome these limits and improve your operations.

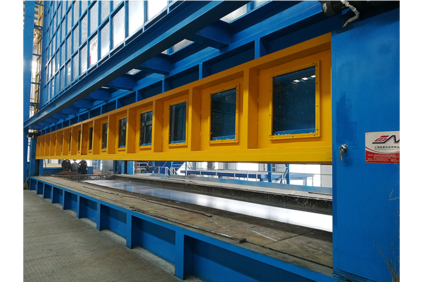

Flux Recycling Unit Process

Waste Separation and Collection

You start the process by collecting unused flux and waste slag right after smelting or welding. This step is important because it keeps the materials dry and free from extra dirt or spatter. Here is how you handle waste separation and collection in a flux recycling unit:

- Collection: Gather unused flux and slag from the smelting or welding area as soon as the process ends.

- Cleaning and Separation: Filter the collected material to remove impurities like small pieces of slag, metal spatter, or debris. This step protects your equipment and ensures the quality of recycled flux.

- Storage: Place the cleaned flux in dry containers. This prevents moisture from causing problems like porosity in future welds or smelts.

- Reuse: Mix the recycled flux with fresh flux, often in a 50:50 ratio. Feed this blend back into your smelting or welding system.

You can see that each step helps you keep the recycled material clean and ready for use. The flux recycling unit uses advanced controls to make these steps easy and reliable.

Treatment and Regeneration

After you separate and collect the waste, you need to treat and regenerate it. The flux recycling unit uses several methods to turn waste slag into reusable flux or auxiliary materials. Here is a summary of the main steps:

| Process Step | Description |

|---|---|

| Collection | Collect waste slag from the metal smelting process. |

| Separation | Separate the slag from other materials to isolate it for treatment. |

| Treatment | Apply drying, screening, heating, or chemical treatment to the slag. |

| Regeneration | Convert the treated slag into usable flux or auxiliary materials for reuse. |

During treatment, you may use different physical or chemical methods. Some common treatments include:

| Treatment Method | Description |

|---|---|

| Chemical Precipitation | Add chemicals to remove heavy metals by forming solids that settle out. |

| Granular Activated Carbon Adsorption | Use porous carbon to capture contaminants, which you can later regenerate for reuse. |

| Zero Valent Iron Treatment | Use elemental iron to reduce and adsorb metal contaminants, making them less harmful. |

These steps help you recover valuable materials and reduce the amount of waste you send to landfills. The flux recycling unit makes the process efficient and safe for your team.

Energy Recovery Features

The flux recycling unit does more than recycle materials. It also helps you save energy by capturing waste heat from the smelting process. Here is how the energy recovery system works:

- The system captures heat from high-temperature gases, liquids, or solids released during smelting.

- You can use this waste heat for hot water production, process heating, cooling, or drying.

- Heat recovery devices let you use the captured heat directly for heat exchange or preheating.

- If the waste heat is not enough, heat pump equipment can add extra energy to meet your needs.

The unit uses advanced heat pump technology to boost energy efficiency. For example, the system can reach a coefficient of performance (COP) of 3.7 with recirculation. This means you get 51–73% higher efficiency compared to older systems. Some units even achieve a maximum energy efficiency ratio of 2.85. In real-world use, the seasonal performance factor (SPF) for ground source heat pumps is around 4. You can expect energy savings up to two or three times greater than with electric heating.

With these features, the flux recycling unit helps you lower your energy bills and reduce your environmental impact. The user-friendly touch-screen controls make it easy for you to monitor and adjust the system as needed.

Tip: By using both material recycling and energy recovery, you can make your smelting operation more sustainable and cost-effective.

Benefits of the Flux Recycling Unit

Environmental Gains

You help protect the environment when you use the flux recycling unit. This system reduces the amount of waste that goes to landfills. You also lower harmful emissions from your smelting process. By recycling slag and other materials, you keep toxic substances out of the soil and water. You support cleaner air and a safer workplace. Many companies see a drop in their carbon footprint after installing this equipment.

Note: Cleaner production means you meet strict environmental rules more easily.

Cost and Resource Savings

You save money every year with the flux recycling unit. You do not need to buy as much new flux or raw material. This system lets you reuse what you already have. You also cut down on waste disposal fees. Many factories report savings of tens of thousands of dollars each year. The unit helps you use resources more wisely. You get more value from every ton of material you process.

| Benefit | How You Save Money |

|---|---|

| Less raw material use | Lower purchase costs |

| Reduced waste disposal | Fewer landfill and treatment fees |

| Energy recovery | Lower heating and cooling bills |

Operational Efficiency

You make your work easier and faster with the flux recycling unit. The system uses smart controls and touch-screen panels. You can monitor the process and adjust settings quickly. The unit recycles materials and recovers energy at the same time. This means you spend less time managing waste and more time making quality metal products. You also improve safety because you handle less hazardous waste.

Tip: A more efficient operation helps you stay ahead in a competitive market.

Real-World Impact

Industry Results

You can see the difference the flux recycling unit makes in real factories. Many companies have reported big changes after installing this system. For example, one steel plant reduced its waste sent to landfills by over 60%. Another aluminum smelter cut its raw material costs by 30%. These numbers show that you can save money and help the environment at the same time.

Factories also noticed better air and water quality around their sites. Workers reported fewer safety risks because they handled less hazardous waste. Some companies even received awards for their green efforts. You can find these results in many parts of the world, from Asia to Europe and North America.

When you use advanced recycling technology, you set a new standard for your industry.

Adoption and Feedback

You might wonder how easy it is to start using a flux recycling unit. Many users say the system is simple to install and operate. The touch-screen controls help you monitor every step. Training your team takes only a short time. Most operators feel confident after just a few days.

Here are some common points from user feedback:

- You save money on raw materials and waste disposal.

- You meet strict environmental rules more easily.

- You improve your company’s image with customers and partners.

- You see quick results, often within the first year.

A plant manager shared,

“We saw a return on our investment faster than we expected. The system runs smoothly, and our team likes the easy controls.”

You can join many others who have made their smelting operations cleaner, safer, and more efficient.

Comparison with Traditional Methods

Efficiency and Sustainability

You may wonder how the new system compares to older ways of handling smelting waste. Traditional methods often involve dumping slag or sending it to landfills. These methods use a lot of energy and create more pollution. You must spend time and money on waste disposal. You also lose valuable materials that could be used again.

The flux recycling unit changes this process. You can recycle slag and other waste right at your facility. This system lets you recover useful materials and cut down on waste. You use less energy because the unit captures and reuses heat from the smelting process. You also lower your emissions and help protect the environment.

Here is a quick comparison:

| Feature | Traditional Methods | Flux Recycling Unit |

|---|---|---|

| Waste sent to landfill | High | Low |

| Energy use | High | Low |

| Material recovery | Low | High |

| Emissions | High | Low |

| Compliance | Hard | Easy |

Tip: Choosing advanced recycling helps you meet green goals and save resources.

Long-Term Value

You get more than short-term savings with modern recycling. Over time, you see big benefits for your business. You spend less on raw materials and waste disposal. You also avoid fines for breaking environmental rules. Your company builds a strong reputation for caring about the planet.

Many factories report that the system pays for itself in just a few years. You can use the savings to invest in other parts of your operation. Workers feel safer because they handle less hazardous waste. Customers trust you more when they see your commitment to clean production.

Remember: Smart investments today lead to a better future for your business and the environment.

You can change your approach to waste management in metal smelting with a flux recycling unit. This technology helps you sort and recycle metals, recover valuable slag, and save energy. You reduce greenhouse gas emissions and cut costs by reusing materials. Industry experts recommend choosing units with high recovery efficiency and strong safety features. By adopting this system, you support a circular economy and help protect the environment for the future.

Post time: Jan-04-2026