You must first define your exact product needs. Detail your key specifications, including size, finish, and design features. You should also establish your required order volume and target budget. This initial planning helps you find the right zinc pot manufacturer. These pots are a form of Materials Handling Equipment for plants.

Key Takeaways

- Clearly define your product needs and budget first. This helps you find the right manufacturer.

- Carefully check suppliers’ details and ask for product samples. This ensures good quality.

- Manage production and shipping closely. This makes sure your order arrives correctly.

Step 1: Defining Your Product and Business Needs

A successful sourcing journey starts with a clear plan. You must first define your product and business goals. This preparation helps you communicate effectively with suppliers. It ensures you receive accurate quotes for the exact products you want.

Detail Your Zinc Pot Specifications

You need to create a detailed list of your product requirements. A specific plan prevents misunderstandings with your manufacturer. Your specification sheet should include key details. Think about every aspect of the final product.

| Specification | Description Examples |

|---|---|

| Material Grade | Galvanized steel, pure zinc alloy |

| Dimensions | Height, diameter (top/bottom), thickness |

| Design Features | Handles, embossed patterns, drainage holes |

| Finish | Rustic, polished, powder-coated (e.g., matte black) |

Tip: Create a technical drawing or a detailed sketch. A visual guide helps a zinc pot manufacturer understand your vision perfectly.

Determine Your Order Volume and Target Price

Next, you must establish your order quantity and budget. Your order volume directly impacts your cost per unit. Manufacturers have a Minimum Order Quantity (MOQ). This is the smallest order they will accept.

Understanding MOQs is essential for finding the right partner.

- A standard zinc flower pot may have an MOQ of 100 pieces.

- Custom options like a logo or special packaging can raise the MOQ to 110 pieces.

Set a target price per pot. This price helps you filter potential suppliers quickly. A realistic budget keeps your business profitable and guides your negotiations later.

Step 2: How to Find a Wholesale Zinc Pot Manufacturer

After defining your product, you can start your search for suppliers. You have several effective methods to find a reliable wholesale zinc pot manufacturer. Combining these strategies will give you the best results.

Using Online B2B Marketplaces

Online B2B marketplaces connect you with thousands of global suppliers. Platforms like Globy offer specific categories for garden supplies, making your search easier. Another popular option is SaleHoo, which has helped over 137,000 entrepreneurs find suppliers since 2005. Users often praise its excellent customer service and verified supplier directory.

Note: When using these platforms, use specific keywords like “galvanized metal planter” or “embossed zinc pot” to find relevant manufacturers.

Attending Industry Trade Shows

Trade shows let you meet suppliers and inspect products in person. You can build relationships and see the latest industry trends. Look for events focused on home, garden, and hardware.

- National Hardware Show (Las Vegas)

- Atlanta Market (Atlanta)

- PAYSALIA (Lyon, France)

- VIETNAM HOME & GARDEN EXPO (Ho Chi Minh)

These events gather many qualified suppliers under one roof, saving you valuable time.

Leveraging Sourcing Agents and Networks

A sourcing agent can be a valuable partner, especially when sourcing from overseas. These professionals have established networks and understand the local business culture. They handle communication, vet factories, and manage logistics for you. You can also ask for recommendations from business groups or professional networks to find a trusted agent or supplier.

Step 3: Vetting and Shortlisting Suppliers

You have a list of potential suppliers. Now you must investigate each one carefully. This vetting process helps you create a shortlist of the most reliable partners. A thorough check protects your investment and ensures product quality.

Reviewing Company Credentials and Certifications

First, you should verify a supplier’s business credentials. Ask for their business license and export license if they are overseas. You also need to check for quality management certifications. These documents prove a factory follows international standards. Look for key certifications relevant to metal fabrication.

- ISO 9001: This shows the company has a strong quality management system.

- AWS D1.1: This standard is for structural welding quality.

- ANSI Z49.1: This certification relates to safety in welding and cutting.

- OSHA Compliance: This shows the factory follows workplace safety rules.

Analyzing Product Catalogs and Specialization

Next, analyze the manufacturer’s product catalog. A supplier specializing in garden or home decor products is often a good sign. A focused zinc pot manufacturer likely has more expertise than a factory that produces unrelated items. You should also watch for red flags in their product offerings.

Pro Tip: Be cautious if a supplier sells products that can be misused. Examples include technology for tracking people or equipment for use in occupied territories. These offerings may signal ethical issues or a lack of focus on your product category.

Checking Customer Reviews and Case Studies

Finally, you must learn about other buyers’ experiences. Look for customer reviews on the B2B marketplace where you found the supplier. You can also check the company’s website for testimonials or case studies. Positive feedback from other businesses is a strong indicator of a trustworthy partner. Do not hesitate to ask the supplier for references you can contact directly.

Step 4: Requesting Quotes and Evaluating Responses

With your shortlist ready, you can now ask for pricing. You will send a Request for Quote (RFQ) to each potential supplier. A detailed RFQ helps you get accurate and comparable proposals.

How to Write a Clear Request for Quote (RFQ)

A strong RFQ gives suppliers all the information they need. It shows you are a serious buyer. Your RFQ should clearly define your project and expectations. Be sure to include your technical drawings and specification sheet from Step 1.

Key items to include in your RFQ:

- Project Scope: Introduce your company and explain the project’s purpose.

- Deliverables: List the exact zinc pots you want to order.

- Timeline: Provide your ideal deadline for receiving the products.

- Budget: Give an estimated target price per unit to guide suppliers.

- Terms: Outline your preferred payment and shipping terms.

Comparing Quotes Beyond Just the Price

The lowest price is not always the best deal. You must evaluate the entire offer to understand the true cost. Look closely at several factors before making a decision. Pay attention to lead time, which is how long it takes to make and ship your order. Also, check the payment terms and any extra fees for tooling or packaging.

Shipping Terms Matter: Understand the shipping terms, or Incoterms. A quote with FOB (Free on Board) means you pay for international shipping. A DDP (Delivered Duty Paid) quote includes shipping and import taxes, which is easier but often more expensive. Always compare the total landed cost.

Other important factors include:

- Minimum Order Quantity (MOQ)

- Quality assurance processes

- Supplier reputation and after-sales support

- Return and refund policies

Step 5: Verifying Quality with Samples and Audits

You have evaluated quotes and are close to choosing a supplier. Now, you must confirm their ability to produce high-quality zinc pots. This step involves getting a physical sample and, for larger orders, conducting a factory audit.

Why Ordering a Physical Sample is Non-Negotiable

You should never place a bulk order without first inspecting a physical sample. Photos and videos cannot show the true quality of a product. A sample allows you to feel the material, check the finish, and test the durability of the zinc pot. It is your best tool to prevent costly mistakes.

You will likely pay for the sample and for express air shipping. Costs vary by weight and courier, but this investment is essential. A heavy metal item like a zinc pot will have shipping costs similar to the cast iron pot shown below.

Example Shipping Costs (Shanghai to NYC)

Product Sample Weight FedEx (USD) UPS (USD) Sneakers 2kg $130 – $205 $135 – $204 Cast iron pot 6.8kg $264 – $363 $272 – $364

Conducting Factory Audits for Large Orders

If you are placing a large or expensive order, you should consider a factory audit. An audit is an in-person inspection of the manufacturer’s facility. It helps you confirm that the supplier has the capability and standards to handle your order. An audit ensures the factory operates ethically and efficiently.

A professional audit will check several key areas:

- Health and Safety: The factory provides a safe workplace with marked exits and protective gear.

- Equipment Maintenance: Machines are properly maintained and calibrated to ensure consistent quality.

- Finished Goods Inspection: The factory has a system to check final products before they ship.

- Supplier Management: They properly vet their own raw material suppliers.

An audit gives you confidence that your partner can deliver quality products on time.

Step 6: Negotiation and Placing the Purchase Order

You have selected your top supplier. Now you can finalize the deal. This step involves negotiating terms and creating a formal contract to protect your investment.

Negotiating Price, Payment Terms, and Lead Times

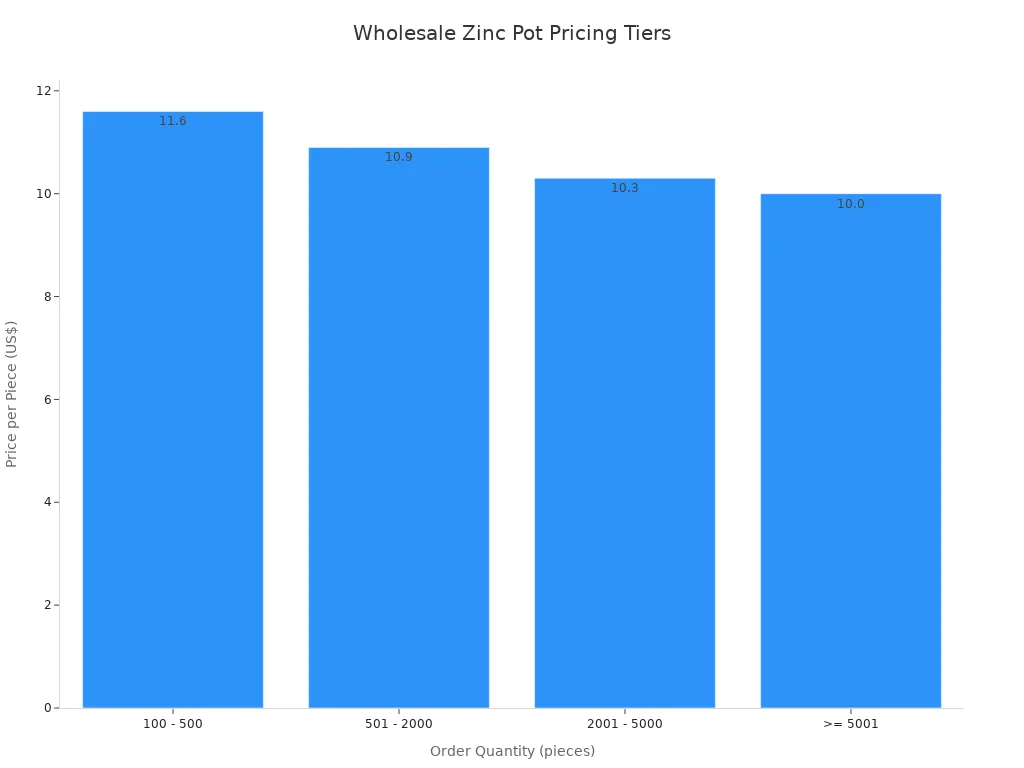

You can often improve the initial quote through negotiation. Many suppliers offer tiered pricing. This means your price per pot decreases as your order quantity increases. You can ask for a bulk discount to get a better deal.

| Quantity (pieces) | Price (US$) |

|---|---|

| 100 – 500 | 11.60 |

| 501 – 2000 | 10.90 |

| 2001 – 5000 | 10.30 |

| >= 5001 | 10.00 |

You also need to agree on payment terms. A common method for international trade is a Telegraphic Transfer (T/T). A typical arrangement is paying a 30% deposit to start production. You then pay the final 70% after the supplier sends you a copy of the shipping documents. Finally, discuss the production lead time to know when your order will be ready.

Creating a Detailed Purchase Order (PO)

A Purchase Order (PO) is your official contract with the manufacturer. It lists all agreed-upon terms and prevents future disputes. Your PO must be clear and comprehensive.

Important: A detailed PO is a legally binding document. It ensures both you and the supplier understand your responsibilities.

Your PO should include several key legal clauses:

- Delivery Terms: Specify shipping responsibilities and timelines using Incoterms.

- Pricing and Payment: Detail the final unit price, total cost, and payment schedule.

- Warranties and Quality: Define the quality standards and what happens if products are defective.

- Acceptance and Rejection: Outline your right to inspect and reject goods that do not meet specifications.

Step 7: Managing Production and Logistics

Your order is placed, but your work is not finished. You must now oversee production and plan for shipping. Good management in this final stage ensures your zinc pots arrive on time and as expected.

Monitoring the Production Process

You should maintain regular contact with your supplier during production. This communication helps you stay informed and prevent surprises. Production delays can happen for many reasons. Understanding these potential issues helps you manage your timeline.

Common causes for delays include:

- Machine Failure: Unexpected equipment breakdowns can halt the entire production line.

- Raw Material Shortages: The factory may have trouble getting the zinc or steel needed for your pots.

- Communication Breakdowns: Misunderstandings between you and the factory can lead to mistakes.

Tip: Ask your supplier for weekly updates with photos or videos. This allows you to see the progress and spot any quality issues before the order is complete.

Arranging Shipping and Customs Clearance

Once production finishes, you need to get your products home. Arranging international shipping and customs can be complex. Many businesses hire a freight forwarder to manage this process. A freight forwarder is a company that organizes shipments for you. They find the best shipping routes and handle all the paperwork.

Your shipment will need several key documents to clear customs:

- Commercial Invoice

- Packing List

- Bill of Lading (for sea freight) or Air Waybill (for air freight)

Your supplier and freight forwarder will help you prepare these forms. Proper documentation prevents your shipment from getting stuck at the port.

You can achieve sourcing success by following these structured steps from start to finish. A well-planned strategy ensures you receive high-quality zinc pots that meet your business standards.

Remember, clear communication and thorough vetting are your best tools. They help you build a strong, profitable relationship with a zinc pot manufacturer and delight your customers.

Post time: Nov-18-2025