Galvanizing is the go-to method for protecting steel from rust. Essentially, a galvanizing bath is a big kettle of molten zinc used to coat metal parts. When clean steel is dipped into this bath, the zinc quickly bonds to the surface, forming a rugged, corrosion-resistant finish. Galvanizing has been around for over 150 years, yet it remains surprisingly efficient and environmentally friendly. In fact, it is often cited as one of the most eco-friendly corrosion-prevention processes available. The result is steel that can survive decades outdoors with minimal upkeep. Below we break down step-by-step how a steel part goes from dusty old metal to zinc-armored, inside a galvanizing bath.

What Is a Galvanizing Bath?

A galvanizing bath is simply a vat of molten zinc heated to about 450°C (842°F). Steel parts are lowered into this hot zinc, which looks like silvery liquid metal. During immersion, the zinc reacts with iron in the steel, creating a metallurgical bond between zinc and steel. In practice, companies often call this the hot-dip galvanizing process – literally dipping steel into “hot” (molten) zinc.

This method is very effective. The zinc bath is typically kept over 98% pure zinc, and conveyor or crane systems carefully angle the steel pieces so that the zinc can flood every corner of the part. Even hollow shapes or tubes fill with zinc, so the inside is coated as well as the outside. As one industry guide puts it, hot-dip galvanizing is a “total immersion” process – steel is fully submerged and zinc coats all interior and exterior surfaces. The steel is raised a few minutes later with a new shiny metal skin on it.

The Hot-Dip Galvanizing Process (Start to Finish)

The galvanizing process has several key stages. Each must be done carefully, because zinc will only stick to a perfectly clean surface. In general, the steps are:

Cleaning (Degreasing & Pickling): First the steel is thoroughly cleaned to remove oils, grease, and loose rust. This usually involves a hot alkali (caustic) solution that degreases the steel. Next, the steel goes into an acid pickling bath (often dilute sulfuric or hydrochloric acid) to eat away mill scale and rust. After pickling, any stubborn dirt, paint or slag is removed manually or by blasting. In short, all contaminants must be gone, because zinc will not bond to dirty steel.

Fluxing: Right before galvanizing, the clean steel is dipped in a flux solution, usually a mix of zinc ammonium chloride. The flux cleans off the last traces of oxide and prevents new oxidation before dipping. In some plants, a thin “flux blanket” even floats atop the zinc bath to help degrease the steel as it enters. The fluxing step is crucial: it ensures the molten zinc can wet the steel evenly.

Immersion in the Zinc Bath: Now comes the heart of the process. The prepared steel is slowly lowered (often at an angle) into the molten zinc kettle, typically held at ~450°C. The image below shows steel beams entering a hot zinc bath. As soon as steel touches the liquid metal, a reaction begins. Zinc begins to alloy with the iron surface, and liquid zinc flows around the entire part. Inside the bath, zinc and iron form several alloy layers by a metallurgical reaction. During this time (usually a few minutes), the coating builds up to its proper thickness. A layer of molten zinc sticks to the steel’s surface and then cools to form a solid outer skin.

Figure: Steel parts being dipped into a hot-dip galvanizing bath. The molten zinc (liquid silver) quickly coats the steel.

The plant operators carefully time the immersion. For most parts, dipping for 4–5 minutes is enough. Larger or insulated parts may need longer to reach full temperature. Once heated through, the part is slowly hoisted out. As it rises, any excess zinc drains off – sometimes aided by vibrating or spinning the piece. The thin shell of zinc that remains will cool and harden, often taking on a bright silvery finish on the outside. In fact, freshly galvanized steel often gleams; the characteristic “spangle” or snowflake-like pattern of crystallized zinc may appear on the surface as it solidifies.

Cooling (Passivation/Quenching): After withdrawal, the coated steel is cooled. This can be done by simple air cooling or by quenching the hot steel in water or a chemical passivation bath. No special curing is needed – the zinc/steel bond is already solid. Any thin outer layer of zinc oxide (white rust) that might form is often just left alone or lightly treated. Unlike painted parts, galvanized steel usually requires no further finishing for durability.

Inspection: The final step is quick visual and technical inspection. Inspectors check that every area is coated and measure thickness. Since zinc only bonds to clean metal, poor spots are easy to spot (bare steel looks bright). Standard gauges measure coating thickness to ensure it meets specifications. At this point the galvanized steel is ready for use, guaranteed to resist corrosion for many years.

Inside the Bath: Metallurgy and Protection

What actually happens to the steel inside the molten zinc is a complex bit of chemistry – and one of the surprising strengths of galvanizing. As the hot steel sits in the bath, zinc atoms diffuse into iron to form several intermetallic compounds. The American Galvanizers Association illustrates this with a cross-section: there is an outer layer of nearly pure zinc (called the eta layer) and beneath it 3 hard alloy layers (called gamma, delta, zeta) right at the steel interface. Remarkably, these zinc-iron alloy layers are harder than mild steel. For example, tiny scratches do not penetrate through this multi-layer coating easily. In practice, a galvanized coating is extremely tough and abrasion-resistant.

Another key advantage is cathodic (sacrificial) protection. Zinc is more electrochemically active than steel. In simple terms, if the coating is scratched to bare steel, the surrounding zinc will preferentially corrode first, protecting the steel. In fact, hot-dip galvanizing is famous for this: one source notes that even if bare steel (as big as ¼ inch) is exposed in a scratch, “no corrosion will begin until all the surrounding zinc is consumed”. This means small nicks don’t require repainting; the zinc sacrifices itself over time.

Over the years exposure to air and rain turns zinc into benign by-products (oxides, hydroxides, carbonates) – the gray patina you might see on old galvanized metal. This zinc patina slowly forms a protective outer crust that further slows corrosion. In fact, fully weathered galvanized steel corrodes about 30 times slower than bare steel. In practice, this means a galvanized coating often lasts 50–60 years or more maintenance-free, depending on environment.

Surprising Advantages of Galvanizing

Galvanizing offers several “wow” factors you might not expect from a simple metal coating:

1.Complete Coverage: Because hot-dip galvanizing immerses the part, it even coats insides of hollow sections and inside of tubes. Threads and hidden corners get zinc, unlike brush-on paints. This total-immersion means rust can’t sneak in from unexpected spots.

2.Built-in Toughness: The zinc-iron layers are inherently hard and abrasion-resistant. In some tests, galvanized steel’s coating was over ten times more abrasion-resistant than typical paint. The outer pure zinc layer (eta) is softer and ductile, giving impact resistance, while the inner alloy layers are harder than steel. This multi-layer bond means galvanized parts survive rough handling and wear.

3.Self-Healing (Cathodic) Protection: As noted, zinc will “sacrifice itself” to guard steel. Small scratches on galvanized steel don’t rust out because the zinc corrodes first (also called cathodic protection). There’s even a name, “sideways creep,” for what happens with painted steel (rust creeping under the paint) – and galvanizing essentially prevents it.

4.Fast Turnaround: Despite the heavy equipment, the actual galvanizing step is quick. Hanging a piece and dipping into zinc takes only a few minutes. Preparation is mostly chemical cleaning, and a well-run plant can process an order in a few days total. In fact, modern galvanizing shops boast 24-hour service for small orders.

5.Long Service Life: A galvanized coating can protect steel for decades without repainting. In typical outdoor (industrial or rural) conditions, it’s common to see 50+ years to first maintenance. This longevity often makes galvanizing more economical than periodic repainting in the long run.

6.Environmental Friendliness: The galvanizing process is relatively clean. Spent zinc is recycled, and there are no volatile organic solvents like in paint. Galvanized steel is 100% recyclable at end-of-life. Industry groups even note galvanizing as “probably the most environmentally friendly” corrosion protection available.

7.Recognizable Finish: Galvanized steel often has a characteristic spangled or snowflake-like pattern on its surface. These silvery crystals are the zinc grains solidifying, and they give galvanized surfaces a distinctive appearance. It’s a visual cue that a genuine hot-dip coating is present.

High-Quality Equipment: Bonan Tech’s Pipe Galvanizing Plant

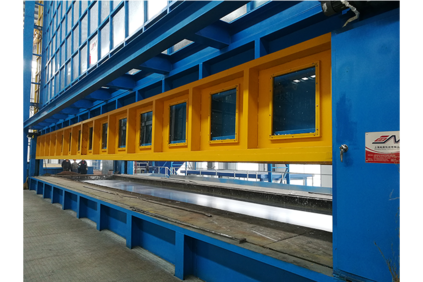

Large galvanizing shops use heavy-duty machinery to run these processes continuously. For example, Bonan Technology Co., Ltd., an equipment manufacturer, emphasizes its “superior grade Pipe Galvanizing Plant” built from high-quality steel and components. Their automated lines handle everything: jigs to hang pipes, alkali degreasing tanks, acid pickles, flux stations, a conveyor through the zinc kettle, and quench tanks. Bonan notes that its pipe galvanizing plants are designed for continuous production across all pipe diameters.

Figure: A continuous pipe galvanizing line in operation. Such automated plants move pipe sections through cleaning, fluxing, and the molten zinc bath.

In a Bonan Tech line, each step is carefully controlled. In fact, pipe galvanizing usually follows these specific stages:

Caustic Cleaning: Pipes enter a hot sodium-hydroxide bath to remove oil and mill scale.

Acid Pickling: Next, they go through an acid bath (usually HCl or H₂SO₄) to dissolve rust and remaining oxides.

Rinsing & Fluxing: After rinsing, pipes are dipped in a zinc-ammonium chloride flux solution, ensuring the steel stays oxide-free before galvanizing.

Drying: Any moisture on the steel is blown off or evaporated by an air dryer.

Immersion (Zinc Bath): The pipes are conveyed into the molten zinc kettle. The hot dip coats them thoroughly with zinc.

Quenching: Finally, the hot galvanized pipes are cooled rapidly in water or a quench bath to lock in the coating.

Every pipe that emerges now has a uniform zinc coating to prevent corrosion. According to Bonan’s description, their “Automatic Galvanizing Machine for Pipes” is capable of handling “the whole range of pipes to be galvanized”, ensuring even very large or small pipes get the proper zinc layer.

Conclusion

The galvanizing bath is more than just a pot of metal – it is the center of a proven, science-driven process that gives steel a virtually self-healing shield. From the cleaning stages to the hot zinc immersion, each step is optimized to produce a durable, metallurgically bonded coating. We’ve seen how galvanized steel not only resists rust but does so surprisingly well – with multi-layer alloys, extreme toughness, and decades of service life.

Whether you’re an engineer specifying a bridge or a homeowner choosing fence posts, understanding the galvanizing bath process helps explain why galvanized steel is so effective. In short, inside that humble bath of molten zinc lies a powerful and surprisingly sophisticated defense system – one that will keep steel structures safe for generations.

Post time: May-21-2025