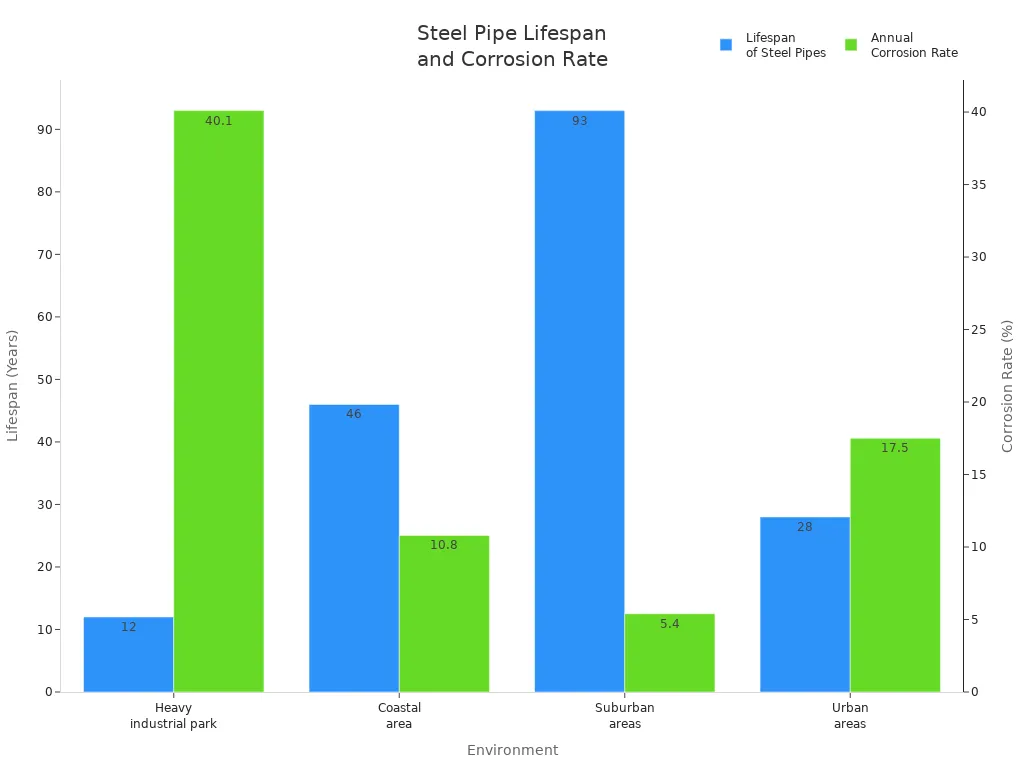

You protect steel pipes from rust by using hot-dip galvanizing. Steel pipe hot-dip galvanizing equipment covers each pipe with zinc, creating a shield against corrosion. Pipes Galvanizing lines help ensure a strong, even finish. Look at the chart below. It shows how galvanized pipes last much longer in different environments.

Key Takeaways

- Hot-dip galvanizing protects steel pipes from rust by applying a thick zinc coating, which acts as a barrier against corrosion.

- Proper surface preparation is crucial. Cleaning and pickling the pipes ensure the zinc adheres well, preventing defects in the coating.

- Galvanized pipes offer long-lasting durability, often lasting 40 to 50 years, making them a cost-effective choice for various industries.

Steel Pipe Hot-Dip Galvanizing Equipment and Process Steps

Steel pipe hot-dip galvanizing equipment helps you protect steel pipes from rust and damage. You use this equipment in many industries, such as construction, machinery, chemical plants, and railways. The equipment handles pipes with diameters from 1/2 to 10 inches and lengths from 4 to 8 meters. It can coat pipes with zinc weighing between 50 and 400 grams per square meter. The equipment can process up to 80,000 tons of steel pipes each year.

| Item | Specification |

|---|---|

| material | steel wire |

| diameter range | 1/2~10 inch |

| pipe length range | 4~8 m |

| coating type | zinc |

| coating weight | 50~400g/m2 |

| capacity | 40000~80000T/year |

Surface Preparation and Cleaning

You start by cleaning the steel pipes. This step removes dirt, oil, and other contaminants. If you skip cleaning, the zinc coating will not stick well. You need to remove weld slag, burrs, mill scale, varnishes, epoxies, sand, oil-based paints, crayon marks, and thick wax or grease. You use degreasing baths with sodium hydroxide to get rid of oils and greases. After degreasing, you rinse the pipes with water. You then use hydrochloric or sulfuric acid to remove rust and mill scale. This step is called pickling.

Tip: Always rinse pipes after acid cleaning to remove all traces of acid. Dry the pipes completely before moving to the next step.

Fluxing the Steel Pipes

Next, you dip the pipes in a flux solution. Fluxing removes any remaining oxides and prevents new oxidation before you coat the pipes with zinc. You use zinc ammonium chloride solution for this step. The best temperature for fluxing is between 60 and 80 °C. This temperature helps the flux clean the steel surface well. The main fluxing agents are zinc chloride and ammonium chloride. These chemicals remove iron oxide and improve the flow of zinc. Fluxing also helps you use less zinc and reduces waste.

- Zinc chloride: 60–80%

- Ammonium chloride: 7–20%

- Fluidity modifying agents: 2–20%

- Other compounds: nickel, cobalt, manganese, lead, tin, bismuth, antimony

Immersion in the Zinc Bath

You then immerse the pipes in a bath of molten zinc. Steel pipe hot-dip galvanizing equipment keeps the zinc bath at the right temperature, usually between 825 and 870 °F (440–460 °C). You keep the pipes in the bath for 5 to 15 minutes. This time lets the zinc bond to the steel and form a strong, even coating. The zinc bath covers every part of the pipe, even inside and around welds.

Note: If you do not control the temperature or time, you may get defects like dross pimples, blisters, or peeling.

Cooling and Final Cleaning

After you remove the pipes from the zinc bath, you cool them in a quench tank. Cooling stops reactions between the zinc and air. You then rinse the pipes with fresh water to remove any leftover chemicals. If you used acid cleaning, rinse the pipes a second time. Dry the pipes with heated air to make sure no moisture remains. This step keeps the surface clean and prevents white rust.

- Rinse with fresh water

- Dry with heated air

- Store pipes in a dry area

Inspection and Quality Testing

You must inspect the pipes to make sure the coating is strong and even. You use visual checks, thickness measurements, and tests for uniformity. You also check for roughness, corrosion, and damage. You measure the pipe’s size and look for leaks. You follow standards like ASTM A500 and EN 10219. These standards help you make sure the pipes will last and resist rust.

Inspection Technique Description Visual inspection Check for smoothness, defects, and corrosion Layer thickness Use meters to measure coating thickness Uniformity Look for peeling or uneven coating Roughness Test surface roughness Corrosion inspection Find scratches or damage Welding quality Check for cracks or slag Chemical composition Test for correct zinc and steel content Mechanical behavior Measure strength and flexibility Dimensional inspection Confirm diameter, thickness, and length Logo and marking Check for correct labels Leakage test Make sure pipes do not have cracks or holes Safety Reminder: Always follow safety rules when using steel pipe hot-dip galvanizing equipment. Inspect pipes for damage and make sure water quality is good to prevent corrosion.

Benefits of Steel Pipe Hot-Dip Galvanizing Equipment

Superior Rust and Corrosion Protection

You get strong protection from rust when you use steel pipe hot-dip galvanizing equipment. The zinc coating forms a thick barrier that keeps water, air, and chemicals away from the steel. This barrier works better than paint or thin coatings. The zinc also protects the steel if the coating gets scratched. Zinc will corrode first, saving the steel underneath.

- The thick zinc layer stands up to harsh weather and chemicals.

- You see this method used for bridges, railings, and outdoor pipes because it lasts longer.

- The zinc coating uses both barrier and sacrificial protection, so your pipes stay safe even if the surface gets damaged.

Scientific studies show that zinc forms special compounds, like ZnO and Zn5Cl2(OH)8, which slow down rust and keep pipes strong in tough environments.

Mechanism Description Barrier Protection Zinc layer blocks water and air from reaching steel. Sacrificial Protection Zinc corrodes before steel, protecting it even if scratched. Natural Weathering Over time, zinc forms extra layers that add more protection. Enhanced Durability and Longevity

You can expect galvanized pipes to last for decades. The thicker the zinc coating, the longer your pipes will last. For example:

Coating Type Expected Lifespan in Moderate Environments G30 5–10 years G90 20 years or more Most galvanized pipes last about 40 to 50 years. In dry places, they can last even longer. If you use steel pipe hot-dip galvanizing equipment, you help your pipes resist rust and damage for many years.

- Pipes in low-humidity areas may last up to 70 years.

- In wet or salty places, the lifespan may be shorter, but still much longer than uncoated steel.

Cost-Effectiveness and Low Maintenance

You save money over time with galvanized pipes. The initial cost is a bit higher than paint, but you spend less on repairs and upkeep. Here is a quick comparison:

Protection Method Initial Cost Life Expectancy (years) Maintenance Costs NPV Hot-Dip Galvanizing 100 25 0 100 Paint System 90 8 169 169 Galvanized pipes need less cleaning and fewer repairs. Their strong coating means you do not have to worry about rust or leaks as often. This makes them a smart choice for big projects and places where you want pipes to last a long time.

Hot-dip galvanizing equipment helps you protect steel pipes for many years. You get reliable performance in different environments.

- Long-term durability depends on environmental conditions.

- Experts say each process step affects coating quality and strength.

Step Impact on Effectiveness Cleaning Improves adhesion and prevents flaws Pickling Affects smoothness and quality Fluxing Ensures uniform zinc flow Immersion Controls thickness and internal quality Inspection Confirms coating meets standards

Post time: Sep-11-2025