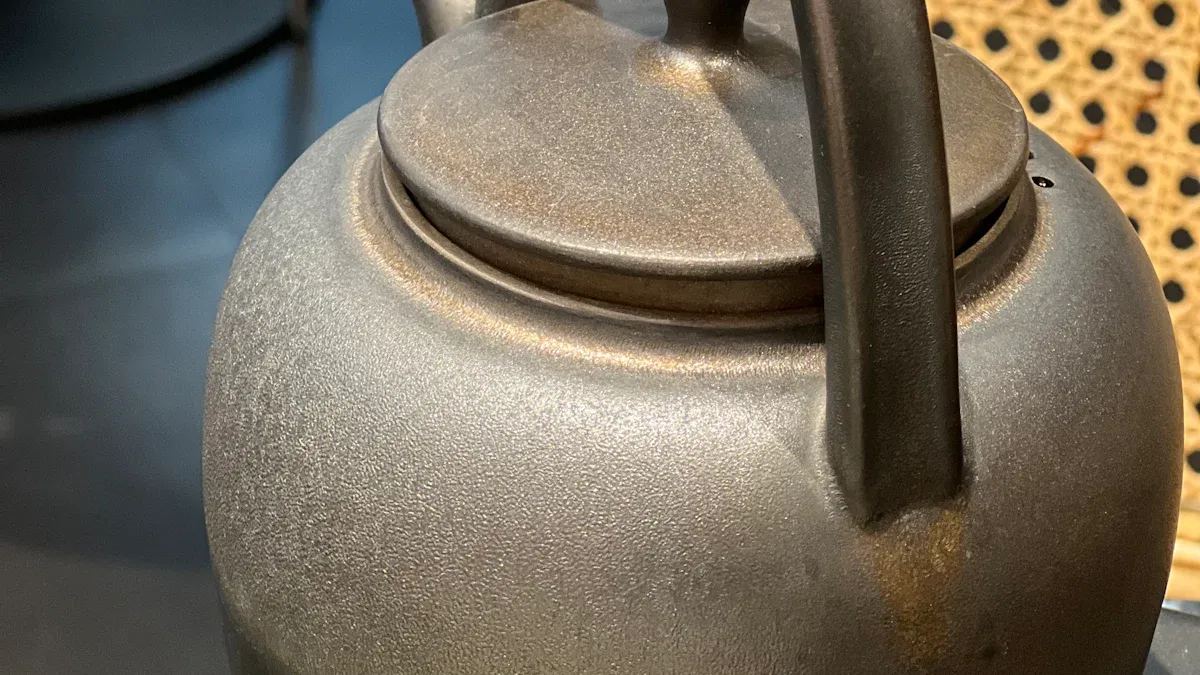

A Zinc Kettle is a large, durable container you use to melt and hold zinc during the galvanizing process. You depend on this essential tool in industrial settings, especially for hot-dip galvanizing steel. The Zinc Kettle helps you achieve high-quality coatings, efficient production, and a safe work environment.

- Modern materials and heating systems boost your production speed.

- Automation and digital monitoring keep your operations safe and reduce downtime.

- Strong construction improves corrosion resistance and extends the kettle’s service life.

Key Takeaways

- A Zinc Kettle is essential for melting and holding zinc during the galvanizing process, ensuring high-quality coatings.

- Choosing the right materials for your kettle, like low-carbon steel, enhances durability and prevents issues like dross formation.

- Maintaining a stable temperature in the kettle is crucial for achieving uniform zinc coatings on steel parts.

- Regular inspections and proper maintenance of the kettle can extend its lifespan and improve workplace safety.

- Understanding the kettle’s role in hot-dip galvanizing helps you produce stronger, corrosion-resistant steel products.

Zinc Kettle Basics

Structure and Materials

You rely on the Zinc Kettle as the heart of your galvanizing operation. Manufacturers build this container using welded steel plates. They choose special steel types to handle high temperatures and resist corrosion from molten zinc. The most common materials include special steel plate, carbon steel, and stainless steel. Each material offers unique benefits for durability and performance.

| Material Type | Description |

|---|---|

| Special Steel Plate | Designed for galvanizing kettles, giving you long service life and strength. |

| Carbon Steel | Used in continuous galvanizing, available in thick plates for extra durability . |

| Stainless Steel | Offers strong corrosion resistance and can handle high temperatures. |

You often see XG08 steel used in China for its low chemical content. This reduces unwanted reactions with zinc and helps your kettle last longer. When you fill the kettle, you use zinc that meets ASTM B6 standards. This means the zinc is at least 98% pure, which helps you get a clean, even coating.

The steel composition matters a lot. Low silicon content (less than 0.03%) keeps the coating stable and reduces corrosion. If the steel has impurities like copper or phosphorus, it can affect how well the zinc sticks and how long the kettle lasts.

Tip: Always check the steel type and purity before installation. This helps you avoid early wear and keeps your operation running smoothly.

Main Functions

You use the Zinc Kettle for several key tasks in your galvanizing plant. Its main job is to hold and melt large amounts of zinc. The kettle keeps the zinc at a steady temperature, usually between 440°C and 460°C. This stable heat is important for making sure the zinc coats your steel parts evenly.

The kettle also prevents dangerous chemical reactions. By using low-silicon, low-carbon steel, you avoid problems like dross formation, which can lower the quality of your coatings. The kettle’s strong structure protects your workplace from leaks or failures, which could cause safety risks and stop production.

Here are the main functions you depend on every day:

- Melting and holding zinc: The kettle keeps hundreds of tons of zinc in liquid form, ready for use.

- Temperature control: It maintains the right heat for efficient galvanizing.

- Zinc replenishment: You can add more zinc as needed, which helps you avoid waste and keep quality high.

- Safety: The kettle’s design reduces the risk of leaks and accidents.

| Aspect | Contribution to Your Workflow |

|---|---|

| Maintenance of Molten Zinc | Ensures you get quality coatings every time. |

| Temperature Control | Keeps your operation efficient and reliable. |

| Zinc Replenishment | Maintains output and prevents coating problems. |

You see how the Zinc Kettle supports every step of your galvanizing process. When you choose the right materials and maintain the kettle well, you boost your plant’s output and keep your workers safe.

Zinc Kettle in Galvanizing

Melting and Storing Zinc

You use the Zinc Kettle to melt and store large amounts of zinc for your galvanizing process. The kettle’s strong steel or cast iron body, often lined with a refractory layer, helps it withstand high temperatures. You keep the zinc bath at about 860°F, which is ideal for melting and maintaining the metal. The kettle’s design limits oxygen exposure, protecting the zinc from unwanted reactions. You also benefit from its large capacity, which lets you process big steel parts and maintain a steady workflow.

| Kettle Dimensions | Zinc Bath Mass |

|---|---|

| 7-10 feet wide | 100,000-300,000 pounds |

| 10-25 feet long | |

| 5-8 feet deep |

Efficient melting and storage depend on the kettle’s material, temperature control, and insulation. You rely on computerized systems and multiple burners to keep the temperature steady. Insulated walls help you minimize heat loss and save energy.

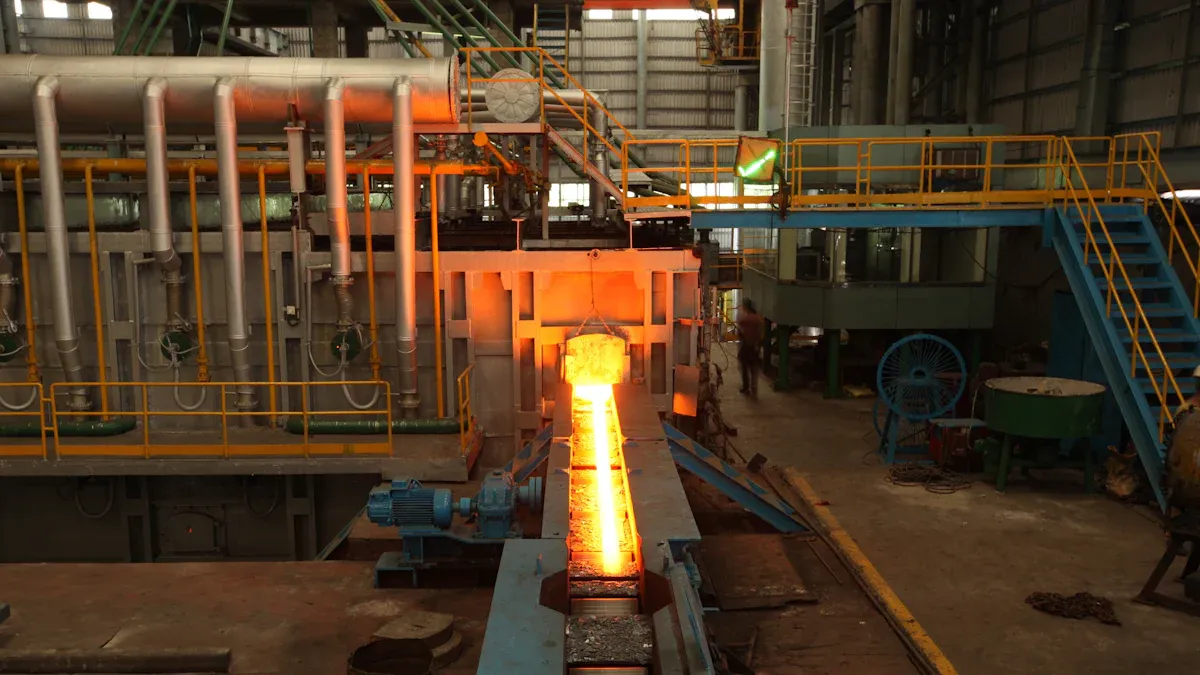

Heating Methods

You have several heating options for your Zinc Kettle. Most galvanizing plants use natural gas because it heats quickly and evenly. You might also use flat-flame furnaces, forced circulation, or high-velocity furnaces. Each method helps you maintain the right temperature for molten zinc.

| Heating Method | Description |

|---|---|

| Natural Gas | The most common heating medium for zinc kettles in galvanizing plants. |

| Flat-Flame Furnace | A type of gas-fired furnace designed for efficient heating. |

| Forced Circulation | This furnace type ensures consistent temperature maintenance of molten zinc. |

| High Velocity Furnace | Another variant of gas-fired furnace that maintains the required temperature for galvanizing. |

You choose your heating method based on your plant’s needs and the size of your kettle.

Role in Hot-Dip Galvanizing

The Zinc Kettle plays a key role in hot-dip galvanizing. You depend on it to keep the zinc at the correct temperature, which helps the coating stick to steel surfaces. The kettle controls immersion time and zinc flow, giving you a uniform coating thickness. If you do not maintain the right temperature, you risk poor adhesion or uneven coatings.

- The kettle keeps molten zinc at the right temperature for proper adhesion.

- It helps you achieve consistent coating thickness by controlling immersion time and zinc flow.

- Correct temperature prevents poor adhesion and uneven coatings.

Tip: Always monitor your kettle’s temperature. Lower temperatures give you thinner, smoother coatings. Higher temperatures create thicker, rougher layers. Consistent temperature control helps you avoid dross formation and ensures high-quality results.

Importance of the Zinc Kettle

Impact on Product Quality

You depend on the Zinc Kettle to deliver high-quality galvanized products. The way you select and operate your kettle affects every coating you produce. If you use the right construction materials, you prevent problems like burning holes and dross formation. These issues can damage your steel and lower the quality of your finished products. The interaction between molten zinc and the kettle material can cause flakes or pits. These defects weaken the protective layer and reduce the lifespan of your steel parts.

- Using firebrick instead of steel in some designs helps you avoid burning holes.

- Careful heating methods and fuel choices keep your coatings smooth and strong.

- Proper kettle operation stops flakes and pits from forming on your products.

The design of your kettle also matters. When you use the right dimensions and drainage systems, you get a uniform zinc coating. This consistency means your products last longer and perform better.

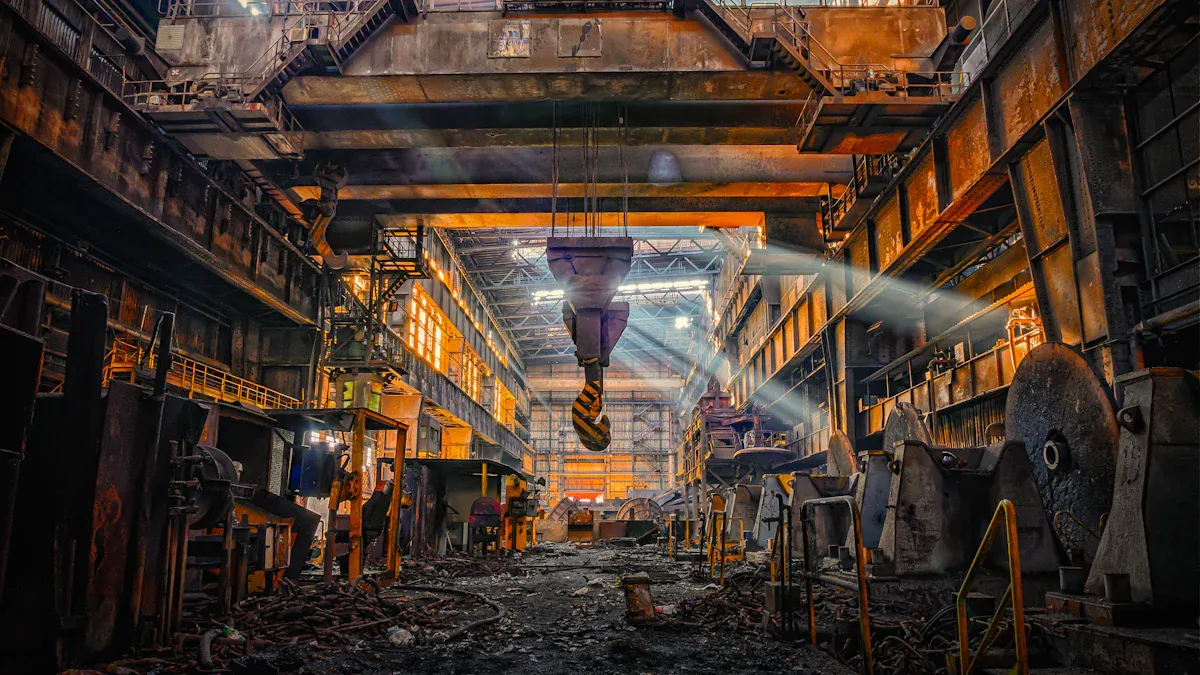

Efficiency and Safety

You improve your production efficiency and workplace safety by maintaining your Zinc Kettle. A well-designed kettle lets you process more steel parts in less time. You avoid delays and keep your workflow steady. Safety is just as important. You face risks like explosions, burns, and fume inhalation if you do not follow best practices. The table below shows common safety incidents and how you can prevent them:

| Safety Incident | Preventive Measure |

|---|---|

| Explosions from moisture in workpieces | Ensure every workpiece is COMPLETELY dry before immersion. |

| Burns from molten zinc | Use proper PPE and follow safe immersion techniques. |

| Inhalation of zinc fumes | Maintain proper ventilation and use appropriate PPE when handling chemicals. |

| General housekeeping hazards | Keep the area around the kettle free of scrap and tripping hazards. |

| Emergency procedures for burns | Cool the burn with running water for at least 20 minutes and remove contaminated clothing. |

| Emergency procedures for fume inhalation | Move the affected person to fresh air immediately. |

Tip: Always train your team on safety procedures and keep your workspace organized.

Corrosion Resistance

You rely on your kettle’s corrosion resistance to protect your investment. Industry standards like ASTM A123 require a minimum average coating thickness of 3.9 mils for structural steel. Inspection ensures you meet these standards and deliver durable products. Hot dip galvanizing gives you a cost-effective way to protect steel from rust. When you choose the right materials for your kettle, you extend its lifespan and reduce maintenance costs.

- Hot dip galvanizing provides long-lasting corrosion protection.

- Regular inspection helps you comply with ASTM, ISO, CSA, and AASHTO standards.

- Thicker coatings mean better durability and less need for repairs.

You see how the Zinc Kettle supports product quality, efficiency, safety, and corrosion resistance in your galvanizing operation.

Maintenance and Installation

Anti-Corrosion Measures

You protect your zinc kettle from corrosion by using high-quality coatings and following regular maintenance routines. These coatings help your kettle last longer, save you money, and keep your workplace safe. When you apply a protective layer, zinc acts as a shield for the steel underneath. This sacrificial protection means zinc corrodes first, stopping rust from reaching the steel.

| Advantage | Description |

|---|---|

| Sacrificial Protection | Zinc corrodes before the underlying metal, protecting it from rust and deterioration. |

| Strong Adhesion | The coating sticks well to metals, forming a tough barrier against moisture and chemicals. |

| Cost-Effectiveness | Zinc coatings cost less than other advanced protection methods. |

Tip: Always check for humidity, temperature changes, and chemical exposure. These factors can weaken your coating and shorten kettle life.

Proper Installation

You ensure safe and efficient operation by installing your zinc kettle correctly. Start with a full inspection of your old kettle and plan the installation to avoid long downtime. Choose the right size and material for your plant. Remove the old kettle with care, then align and weld the new one with precision. Inspect furnace linings, supports, and burners before you start. Upgrade your controls and automation systems for better energy use. Test for leaks and performance before running at full capacity.

- Evaluate the kettle’s condition before installation.

- Plan the process to minimize downtime.

- Select the right kettle material and size.

- Align and weld the kettle with care.

- Inspect and upgrade furnace components.

- Calibrate temperature controls.

- Train your team on maintenance routines.

Common Issues

You may face problems like mottling, ash staining, or black spots on your galvanized products. These issues often come from chemical imbalances, trapped water, or poor rinsing. You can prevent them by controlling the chemical composition, applying coatings properly, and rinsing thoroughly. Regular maintenance helps you spot surface irregularities early and keeps your kettle running smoothly.

- Mottling: Control chemical composition during cooling.

- Ash staining: Apply coatings carefully and avoid trapped water.

- Black spots: Rinse workpieces thoroughly.

- Lumps and runs: Adjust withdrawal speed and bath temperature.

- Peeling: Ensure proper coating application.

Regular maintenance and careful installation help you avoid costly repairs and keep your zinc kettle working at its best.

You rely on the Zinc Kettle to create strong, corrosion-resistant coatings for steel. Its smart design and durable materials help you achieve reliable results and long-term savings. When you understand how it works and keep it well maintained, you get these benefits:

- Lower costs and less maintenance over time

- Long-lasting protection for steel, even in harsh weather

- Consistent, high-quality coatings that last for decades

Remember, your attention to kettle care and operation leads to safer, more efficient galvanizing every day.

FAQ

What is the main purpose of a zinc kettle?

You use a zinc kettle to melt and hold zinc for hot-dip galvanizing. This process helps you coat steel parts with a protective zinc layer, making them last longer.

How do you keep a zinc kettle in good condition?

You should inspect your kettle often. Clean it regularly and apply anti-corrosion coatings. Always follow the manufacturer’s maintenance tips to extend its lifespan.

Which heating methods can you use for a zinc kettle?

You can use natural gas, electric heaters, or high-velocity furnaces. Each method helps you keep the zinc at the right temperature for galvanizing.

Tip: Always monitor the temperature to avoid coating problems.

Why does the kettle material matter?

The material affects how long your kettle lasts and how well it resists corrosion. Low-carbon, low-silicon steel works best because it handles high heat and molten zinc without breaking down.

Post time: Dec-24-2025