Managers identify critical performance gaps, from furnace inefficiencies to outdated control systems. A modern Galvanizing Production Line Factory prioritizes upgrades with the highest return, including on Small Parts Galvanizing lines(Robort). They implement modernization in planned phases to minimize operational downtime.

Key Takeaway: This strategic approach delivers tangible benefits. These include enhanced product quality, lower operational costs, and increased overall profitability. ��

Key Takeaways

- Start with a full check of your mill to find problems and decide what to fix first.

- Upgrade old systems with new technology to make your mill work better and save money.

- Train your team on new tools and keep improving to make sure your mill stays efficient.

Step 1: Conduct a Comprehensive Line Audit

A successful modernization starts with a thorough audit. This initial step provides a clear roadmap for improvement. It identifies specific weaknesses before any investment occurs. A detailed audit helps managers understand the true state of their operations.

Pinpoint Process Bottlenecks

Managers first identify areas that slow down production or degrade quality. These bottlenecks often reveal themselves as recurring product defects. A careful inspection can uncover many common issues. These problems directly impact profitability and customer satisfaction.

- Dross Inclusions: Small particles of zinc-iron alloy can compromise the coating’s corrosion resistance.

- Bare Spots: These uncoated areas often result from poor surface preparation or excess aluminum in the kettle.

- Flaking: Heavy coatings can create high stress, causing the zinc layer to detach from the steel.

- Lumps and Runs: These occur from incorrect withdrawal speeds or improper bath temperatures.

- Mottling: Matte grey patches can form due to high silicon or phosphorus content in the steel.

Evaluate System Health

Next, teams must assess the condition of core equipment. This includes the furnace, drives, and control systems. An aging system may struggle to maintain consistent speed and temperature. This directly affects throughput and energy consumption. A modern Galvanizing Production Line Factory must align its capacity with its operational speed.

Galvanizing line speed typically ranges from 3-30 m/min. Throughput capacity is a key consideration to match line speed with production volumes.

Analyze Performance Data

Data provides objective insights into line efficiency. Managers should collect and analyze key performance indicators (KPIs). This information highlights trends and confirms the impact of bottlenecks. Tracking these metrics is essential for measuring the success of future upgrades. Key data points include:

- Production output

- Equipment utilization

- Maintenance costs

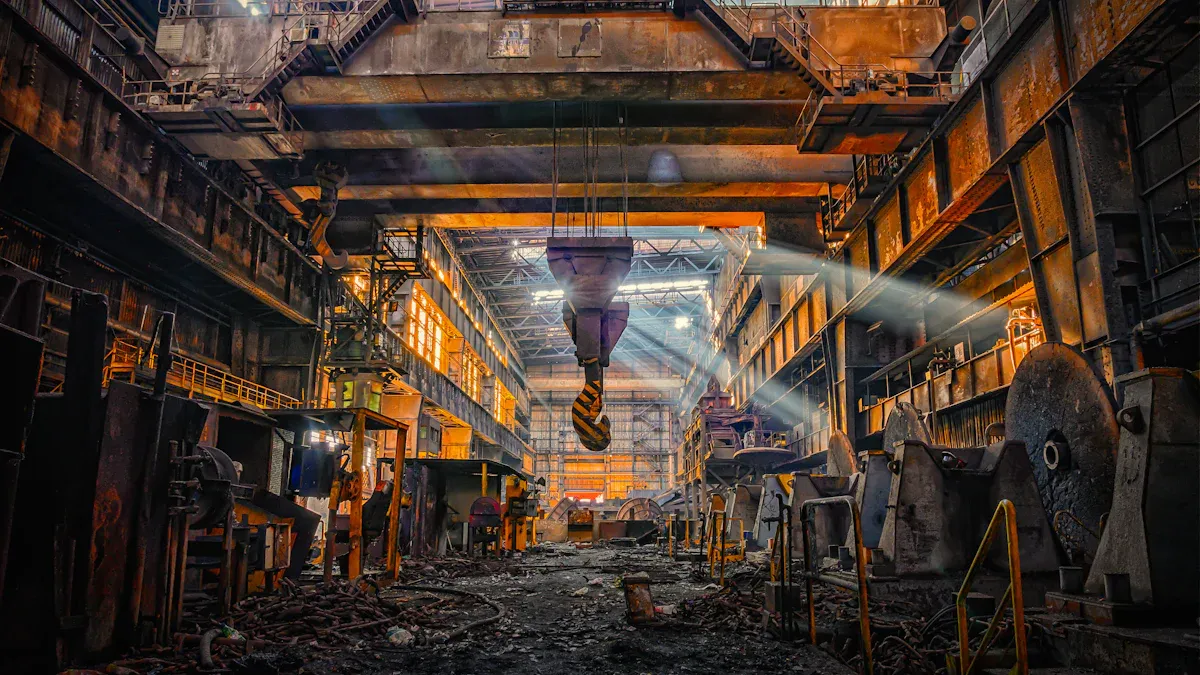

Step 2: Prioritize Key Technical Upgrades

Image Source: unsplash

After a thorough audit, managers can pinpoint which technical upgrades will deliver the highest return on investment. Focusing on process control, mechanical systems, and quality control creates a powerful foundation for a modern, efficient, and profitable operation.

Modernize Process Control and Automation

Outdated control systems are a primary source of inefficiency. Modern automation streamlines production, minimizes downtime, and allows for quick changeovers between different steel grades. Upgrading to a Level 2 automation system provides a centralized brain for the entire line. Key features include:

- A real-time Process Control Computer System.

- Migration of older code (like FORTRAN) to modern languages such as C#.

- Development of intuitive user interfaces (UIs).

- Transition from file-based data storage to robust Oracle databases.

Modern Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) empower operators to make smarter, faster decisions. These systems provide a fully visualized operation through real-time dashboards. Operators can monitor key performance indicators (KPIs) like Overall Equipment Effectiveness (OEE) and throughput to identify trends and boost efficiency.

An intuitive HMI acts as a bridge between the operator and the machine. It converts raw data from sensors and control networks into actionable insights, reducing response times for diagnostics and alarms. ��

This integration enables proactive maintenance. The PLC can track hundreds of data points, like motor vibration and bearing temperature, and alert teams to potential issues before a failure occurs. This allows maintenance to be scheduled during planned shutdowns instead of reacting to costly breakdowns. The return on these investments is often swift and significant.

| Company | System Implemented | Operational Cost Reduction | Production Output Increase |

| SteelTech Inc. | Automated inventory tracking, predictive maintenance | 15% | 20% |

| Steel Manufacturer | Automated energy management system | 3% annually | 1.35% bottom line boost |

Upgrade Drives and Mechanical Systems

The physical equipment of the line is just as critical as its control system. Aging drives and mechanical components are frequent points of failure, leading to unplanned downtime and inconsistent product quality.

A primary upgrade is the transition from older DC drives to modern AC vector drives. AC drives offer superior performance and lower lifetime costs. They maintain an excellent power factor at all speeds, reducing energy consumption by up to 15% in some cases.

| Drive Type | Maintenance Requirement | Reliability |

| AC Drives | Low (no brushes or commutators) | High (solid-state design) |

| DC Drives | High (brushes and commutators) | Lower (subject to mechanical wear) |

Furthermore, AC motors are better suited for the dusty environment of a galvanizing mill. Their externally cooled design prevents contamination, unlike internally cooled DC motors that require filtered air. Technologies like Direct Torque Control (DTC) give AC drives precise speed and torque control, often eliminating the need for external feedback devices.

Mechanical failures, especially weld joint breakages, can stop a line for up to 48 hours. These failures often stem from improper welding parameters or material fatigue. To combat this, managers should invest in robust mechanical components. Upgrading pot roll bearings is a high-impact improvement.

| Upgrade Type | Material/Configuration | Performance Improvement |

| Bearing Material | Al2O3 (Alumina) coatings | Superior corrosion resistance in Zn-Al and Zn-Al-Mg baths. |

| Bearing Configuration | Pairing SS 316L coated with Al2O3 and Wallex6TM | A potential configuration for enhanced durability and performance. |

Integrate Advanced Quality Control

A modern Galvanizing Production Line Factory moves quality control from a final inspection step to an integrated, real-time process. This shift reduces scrap, saves raw materials, and ensures every product meets stringent standards.

Automated surface inspection is a cornerstone of modern quality control. These systems use AI-powered vision and high-resolution cameras to detect defects in real time at speeds up to 1,200 meters per minute. They can identify:

- Uneven zinc coating

- Rust spots and oxidation

- Voids and pinholes

- Surface streaks and scratches

Another critical upgrade is the integration of real-time coating weight gauges. These non-destructive sensors continuously monitor the zinc coating during production. This allows for immediate, automatic adjustments to the air knives, ensuring a uniform coating that meets specifications without costly over-coating. The result is significant zinc savings, improved product consistency, and higher overall mill yield.

These technologies help facilities consistently meet key industry standards for quality and appearance.

Key standards include ASTM A123/A123M for iron and steel products and ISO 1461 for fabricated assemblies. Adhering to these ensures global market acceptance.

By integrating these advanced systems, managers transform quality control from a cost center into a value driver, enhancing brand reputation and customer satisfaction. ✅

Step 3: Plan and Execute the Modernization Project

A successful upgrade depends on careful planning and execution. This step transforms the audit and technical priorities into a concrete action plan, minimizing disruption and maximizing the return on investment.

Develop a Phased Implementation Schedule

Managers should avoid a complete shutdown by breaking the project into manageable phases. A full-scale modernization can take years; for example, one plant retrofitted its drives over a five-year period. This approach allows work to occur during shorter, planned production breaks. A clear plan involves several steps:

- Decompose the project into smaller parts, like modules or features.

- Assess the complexity of each part (e.g., small, medium, large).

- Prioritize components based on business value and risk.

- Group components into logical phases to balance the workload.

- Schedule each phase with clear timelines and milestones.

Manage Project Risks and Contingencies

Every project has potential setbacks. Proactive risk management protects the timeline and budget. Managers should identify potential downtime events and create detailed response procedures. Using data from predictive maintenance systems helps make these contingency plans more accurate.

| Potential Risk | Mitigation Strategy |

| Unexpected Downtime | Create a dedicated response team with clear roles. |

| Supply Chain Delays | Maintain an inventory of critical spare parts. |

| Equipment Complications | Develop robust contingency plans for unforeseen issues. |

Utilize Prefabrication and Off-Line Testing

To reduce on-site installation time, teams can build components in a controlled factory setting. Prefabricating elements like wiring harnesses and control enclosures allows for parallel workflows, as on-site foundation work can happen at the same time. This strategy minimizes construction waste and shortens the overall project duration.

Before any new system goes live, it must undergo off-line testing. A Factory Acceptance Test (FAT) certifies that the system works as designed. This process catches the vast majority of issues before equipment ever reaches the field, saving significant time and money during commissioning. ✅

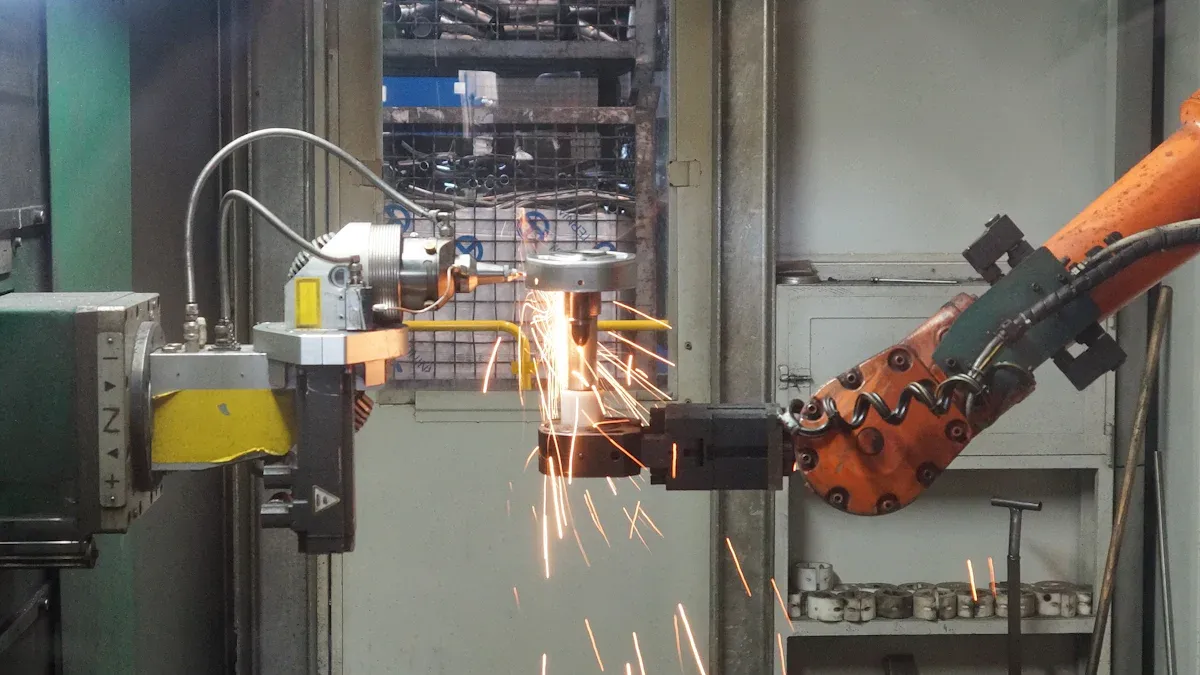

Step 4: Optimize Your Modernized Galvanizing Production Line Factory

Image Source: unsplash

Modernization does not end with installation. The final step is to optimize the human element. This ensures the new technology delivers its full potential. Proper training, updated procedures, and a forward-thinking culture are essential for long-term success.

Train Personnel on New Systems

New technology requires new skills. Managers must provide comprehensive training for all personnel. This prepares teams to use new automation systems effectively. Effective training combines technical instruction with hands-on workshops and simulations. This approach builds operator confidence in a safe, controlled environment. Well-trained maintenance staff offer significant benefits:

- Faster problem identification

- Reduced unplanned downtime

- Improved equipment longevity

- Enhanced operational stability

Ongoing training is vital. It helps teams keep pace with rapid technological advancements. This commitment ensures the modernized Galvanizing Production Line Factory remains efficient and competitive.

Update Standard Operating Procedures

Modern equipment makes old procedures obsolete. Teams must update Standard Operating Procedures (SOPs) to reflect new operational and safety protocols. This includes documenting new equipment usage, emergency responses, and routine maintenance schedules. Safety is the top priority.

| Safety Update | Action Required |

| Pre-Operational Checks | Perform daily inspections for wear, leaks, or malfunctions. |

| Safety Features | Train operators on automatic shut-offs and sensors. |

| Manufacturer Guidelines | Adhere strictly to all operating and maintenance manuals. |

| Personal Protective Equipment (PPE) | Ensure all staff wear appropriate gear like hard hats and safety glasses. |

Foster a Culture of Continuous Improvement

The ultimate goal is a culture of continuous improvement. Leadership must champion this mindset. They can engage employees at all levels and encourage ideas for further optimization. A modern Galvanizing Production Line Factory thrives on feedback.

Shift workers possess firsthand knowledge of bottlenecks and inefficiencies. Their feedback provides valuable operational intelligence that can drive process improvements and innovation.

Managers should establish clear feedback loops. This allows employees to identify problems and suggest solutions. Celebrating successes and acting on feedback reinforces a culture where every team member contributes to ongoing optimization. ✅

A successful modernization follows a clear path.

- It begins with a thorough audit to identify specific weaknesses.

- Managers focus investments on high-ROI areas like automation.

- A phased plan minimizes downtime during execution.

The ultimate goal is a more efficient, profitable, and competitive operation, not just new equipment. ✅

Post time: Oct-21-2025