You want hardware that lasts. Galvanized screws and nuts usually outlast zinc-plated options, especially outdoors. Just look at the numbers below:

| Type of Screw/Nut | Lifespan in Outdoor Applications |

|---|---|

| Galvanized Screws/Nuts | 20 to 50 years (rural), 10 to 20 years (industrial/coastal) |

| Zinc-Plated Screws | A few months to 2 years (dry climate), less than 1 year (humid), only a few months (coastal) |

If you use proper Screw and Nut Galvanizing Equipment, you get reliable protection. Galvanizing Equipment makes a clear difference in durability.

Key Takeaways

- Galvanized screws and nuts last significantly longer than zinc-plated options, making them ideal for outdoor projects.

- The zinc coating on galvanized fasteners provides excellent corrosion resistance, protecting them from rust in harsh environments.

- Choosing galvanized hardware can lead to cost savings over time due to reduced maintenance and fewer replacements.

Key Benefits of Galvanized Screws and Nuts

Corrosion Resistance

You want your screws and nuts to last, especially in tough environments. Galvanized fasteners have a zinc coating that protects them from rust. This layer acts as a shield against moisture and chemicals. You can use these screws and nuts outdoors, in humid areas, or near the sea.

The study examined the atmospheric corrosion performance of galvanized steel bolts in a marine environment over two years. It found that the zinc coating provided minimal protection to the underlying steel substrate, and despite the formation of a dense rust layer, the fastener degradation was critical, indicating high susceptibility to exfoliation and potential thread stripping.

Galvanized steel does not match the corrosion resistance of stainless steel, but it still offers better protection than plain steel. You can see the difference in the table below:

| Material | Corrosion Resistance | Notes |

|---|---|---|

| Galvanized Steel | Lower than stainless steel; zinc coating can wear off leading to rust | Cheaper option, but less durable in harsh environments. |

| Stainless Steel | Superior corrosion resistance due to chromium oxide layer; resistant even when scratched | More expensive, but offers long-term durability and rust protection. |

Long-Term Durability

You need hardware that stands the test of time. Galvanized screws and nuts last much longer than zinc-plated ones. The zinc coating helps them resist damp environments and severe weather. You can rely on them for outdoor projects like fences, bridges, and decks.

- Heavy-duty galvanized screws offer impressive strength and durability for outdoor projects.

- They are a cost-effective alternative to stainless steel, making them a practical choice for many applications.

- Galvanized screws are effective for outdoor projects due to their zinc coating, which helps them resist damp environments and severe weather.

- They provide a strong connection for structures like fences, making them a durable choice for outdoor applications.

You can compare the lifespan of different fasteners:

- Zinc-plated screws: 10-15 years indoors, 1-3 years outdoors in exposed areas.

- Hot-dip galvanized screws: Over 50 years indoors, 10-20 years outdoors, 5-7 years near the sea.

- 304 stainless steel screws: Lifetime indoors, 30+ years outdoors, 10-15 years in marine spots.

- 316 stainless steel screws: Lifetime in almost all environments, over 25 years by the ocean.

- Silicon bronze screws: 50+ years in salty waters.

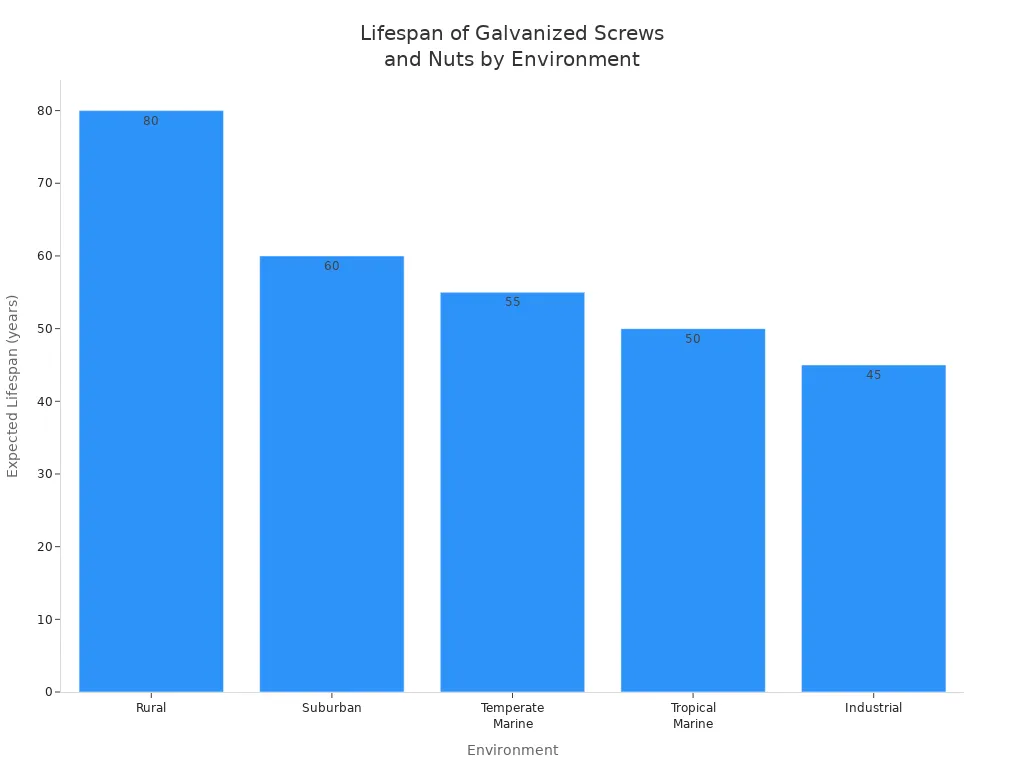

Galvanized screws and nuts can last for decades in many environments. The chart below shows how long you can expect them to last:

| Environment | Expected Lifespan |

|---|---|

| Rural | 80+ years |

| Suburban | 60+ years |

| Temperate Marine | 55+ years |

| Tropical Marine | 50+ years |

| Industrial | 45+ years |

Cost Savings Over Time

You save money when you choose galvanized screws and nuts. These fasteners need less maintenance and fewer replacements. You spend less on repairs and labor over the years.

- Reduced Maintenance Costs: Galvanized steel requires minimal maintenance over its lifetime, leading to significant savings on maintenance expenses.

- Extended Lifespan: The longer lifespan of galvanized steel reduces the need for frequent replacements, further contributing to cost savings.

You get more value for your investment. Galvanized hardware helps you avoid unexpected costs and keeps your projects strong for years.

Versatility in Different Environments

You can use galvanized screws and nuts in many places. They work well outdoors, in wet areas, and in places with changing weather. Their zinc coating makes them a top choice for construction and outdoor projects.

Galvanized screws and nuts excel in outdoor and high-moisture environments due to their enhanced durability and corrosion resistance, making them a preferred choice for construction and outdoor projects.

Many industries rely on galvanized hardware because it adapts to different conditions. You can see some common uses in the table below:

| Industry | Application Description |

|---|---|

| Structure | Used in framework assemblies and engine mechanisms, providing resistance to vibration, heat, and moisture. |

| Automotive | Essential for various components, ensuring durability and cost-effectiveness. |

| Agriculture | Utilized in fixing equipment and machinery, exposed to moisture and chemicals, enhancing lifespan. |

| Coastal Industries | Beneficial due to zinc coating that protects against saltwater corrosion. |

| Industrial | Critical for fastening machinery, metal frameworks, and HVAC systems in harsh environments. |

You can trust galvanized screws and nuts to perform in many settings, from farms to factories to coastal buildings.

Main Drawbacks of Galvanized Hardware

Hydrogen Embrittlement Risk

You need to know about hydrogen embrittlement before choosing galvanized screws and nuts. This problem happens when hydrogen enters the metal and makes it brittle. Brittle metal can crack or break under stress.

Several factors increase the risk of hydrogen embrittlement:

- Corrosion, especially in acidic or salty environments, generates hydrogen on metal surfaces.

- Moisture plays a big role, especially in places with high humidity.

- Exposure during construction, like working in wet conditions, can speed up hydrogen penetration.

- Service conditions with uncertain or high humidity levels raise the risk.

You also face higher risk when these three things happen together:

- Hydrogen is present.

- The fastener is under constant load or stress.

- The material is susceptible, especially high-strength steel.

Unintentional stress during installation can overload screws and make embrittlement more likely. You should always control stress sources and avoid over-tightening fasteners.

Tip: If you use galvanized fasteners in wet or corrosive environments, check for signs of cracking or loss of strength over time.

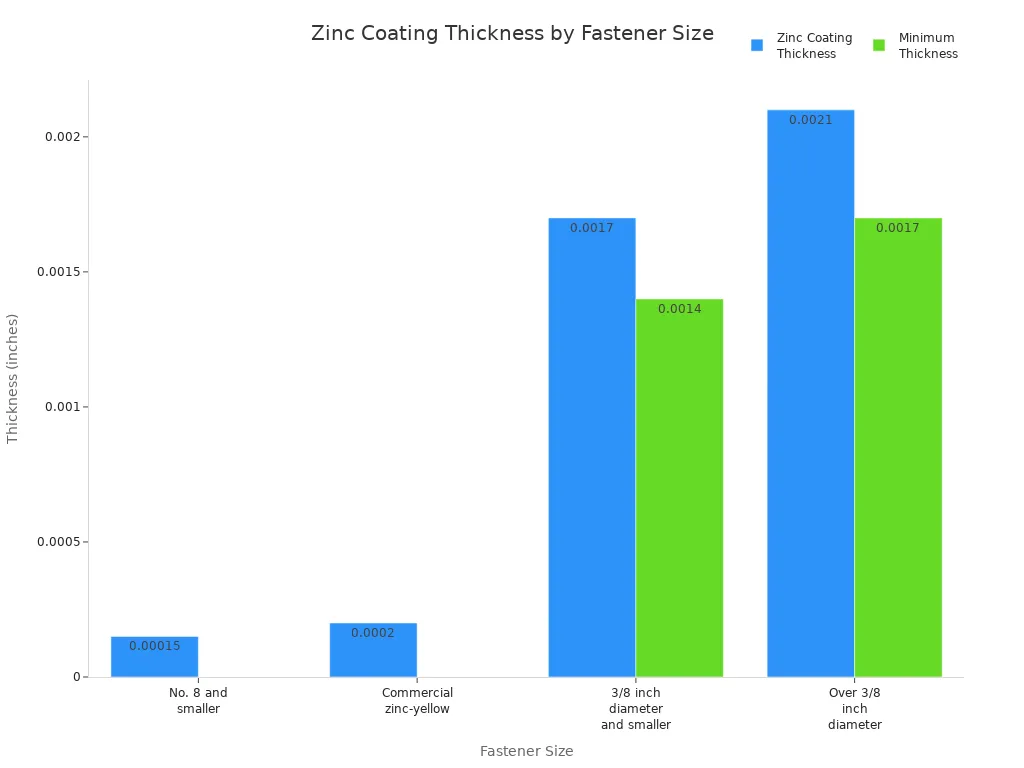

Fastening Issues from Zinc Coating Thickness

Galvanized screws and nuts have a thick zinc coating. This coating protects against rust, but it can cause problems when you try to fasten parts together. The thickness of the zinc layer can make the screws and nuts hard to fit into holes or threads.

| Aspect | Detail |

|---|---|

| Zinc Coating Thickness Range | 45–65 μm |

| Impact on Fastening | Thicker coatings require overtapping of holes to fit the fasteners, affecting secure fastening. |

| Corrosion Protection | Zinc coating on male threads protects both components from corrosion despite overtapping. |

Industry standards set limits for zinc coating thickness to prevent fastening problems. Zinc plating usually gives a thin, shiny layer, good for small fasteners in mild conditions. Hot-dip galvanizing creates a much thicker layer, which works better in harsh environments but can make fastening more difficult.

| Fastener Size | Zinc Coating Thickness (inches) | Minimum Thickness (inches) |

|---|---|---|

| No. 8 and smaller | 0.00015 | Thinner coating acceptable |

| Commercial zinc-yellow | 0.00020 | Thinner coating acceptable |

| 3/8 inch diameter and smaller | 0.0017 | 0.0014 |

| Over 3/8 inch diameter | 0.0021 | 0.0017 |

- Commercial zinc plating has a minimum thickness of 0.00015 inches.

- Hot dip galvanizing provides a thicker and more durable coating, about 1.0 mm thick.

- Zinc plated fasteners work well in mild environments, but hot-dipped galvanized fasteners are better for tough conditions.

Not Ideal for High-Stress Uses

Galvanized screws and nuts do not perform well in high-stress or load-bearing applications. You may see problems like cracking or sudden failure if you use them where strong forces are present.

The risk of hydrogen embrittlement is higher for fasteners with tensile strength above 150 ksi. This issue causes the metal to lose ductility and break early. Industry standards, such as ASTM A143 and ASTM F2329, warn against using hot-dip galvanized fasteners for high-strength jobs.

In high-stress environments, galvanized bolts can suffer from stress corrosion cracking and hydrogen-induced cracking. Their strength can drop by over 20% after long-term use. The hydrogen content in these bolts can increase by more than 300%, making them more likely to fail. High-strength coated bolts keep their mechanical properties better under stress.

Note: For bridges, heavy machinery, or structural supports, you should choose fasteners made from high-strength materials like stainless steel or alloy steel.

Compatibility Concerns with Other Materials

You must consider compatibility when using galvanized screws and nuts with other building materials. Some combinations can cause rust or chemical reactions that weaken your project.

Several independent sources have warned that white and red rust quickly forms when hot dipped galvanized fasteners are tested with non-arsenate treated wood. According to an EPA report, ‘[t]here has been one age-accelerated test conducted by the building industry which indicates that even hardware that advertises the improved resistance to corrosion begins to show signs of rust within 1000 hours of age-accelerated testing (equivalent to 16 years of installed exposure) when used with ACQ-treated wood.’

- Preservative-treated lumber can be incompatible with zinc plated screws and aluminum.

- Stainless steel fasteners or hot dip galvanized nails made to ASTM A153 Class D or heavier work best with treated lumber.

- When attaching metal panels to treated wood, you can use a moisture barrier between the lumber and the panel.

- Fasteners that are not compatible include zinc plated screws, zinc-alloy headed screws, and stainless capped screws.

Chemical reactions can also happen between galvanized coatings and concrete, especially during curing. This process releases hydrogen gas and weakens the bond between galvanized rebar and concrete. Chromate treatments help reduce these problems.

Alert: Always check the compatibility of your fasteners with the materials in your project. Using the wrong combination can lead to early rust, weak joints, or even structural failure.

When to Use Galvanized Screws and Nuts

Best Project Applications

You get the most value from galvanized screws and nuts in projects that face weather, moisture, or outdoor exposure. Industry experts recommend these fasteners for several key uses:

- Outdoor Projects: You can use galvanized screws for fences, decks, and outdoor furniture. Their corrosion resistance keeps your work strong even in rain or sun.

- Construction Projects: Builders often choose galvanized fasteners for structural frames and general construction. You benefit from their durability and lower cost.

- Woodwork and Decking: Galvanized screws work well with treated lumber. They help prevent stains and wood damage over time.

Tip: Building codes often require hot-dipped galvanized, stainless steel, or silicon bronze fasteners for projects with preservative-treated wood. For roofing, you should use galvanized fasteners to meet safety standards.

| Application Type | Fastener Requirement |

|---|---|

| Roofing | Galvanized fasteners for steel roofs |

| Preservative-Treated Wood | Hot-dipped galvanized steel, stainless steel, silicon bronze, or copper fasteners required. |

When to Consider Alternatives

You should look at other fastener types if your project faces extreme stress, chemicals, or saltwater. Stainless steel fasteners work best for marine, food processing, or medical settings. They last longer and resist rust better than galvanized steel, especially in harsh environments.

| Fastener Type | Best For | Pros | Cons |

|---|---|---|---|

| Stainless Steel | Marine, food, medical, outdoor | Long-lasting, corrosion-resistant | Higher cost |

| Zinc Plating | Dry, mild environments | Affordable, basic rust protection | Not for harsh or wet conditions |

| Phosphate Coating | Military, automotive, industrial | Good lubrication with oil | Moderate corrosion resistance |

Galvanized coatings protect steel in seawater, but salt and chemicals can wear them down quickly. Stainless steel offers better long-term performance in these tough spots. Choose the right fastener for your environment to keep your project safe and strong.

Choosing Quality Galvanized Fasteners

Post time: Sep-24-2025