Zinc Kettle

Product Description

The zinc melting tank for hot-dip galvanizing of steel structures, usually called the zinc pot, is mostly welded with steel plates. The steel zinc pot is not only easy to make, but also suitable for heating with various heat sources, and easy to use and maintain, especially suitable for supporting the use of large steel structure hot-dip galvanizing production line.

The quality of hot-dip galvanized coating and production efficiency are closely related to the process technology used and the life of the zinc pot. If the zinc pot is corroded too quickly, it will lead to premature damage or even zinc leakage through perforation. The direct economic loss and indirect economic loss caused by production stoppage are large.

Most impurities and alloying elements will increase the corrosion of steel in zinc bath. The corrosion mechanism of steel in zinc bath is completely different from that of steel in atmosphere or water. Some steels with good corrosion resistance and oxidation resistance, such as stainless steel and heat-resistant steel, have lower corrosion resistance to molten zinc than low-carbon low silicon steel with higher purity. Therefore, low-carbon low silicon steel with higher purity is often used to make zinc pots. Adding a small amount of carbon and manganese () into steel has little effect on the corrosion resistance of steel to molten zinc, but it can improve the strength of steel.

Use of zinc pot

- 1. Storage of zinc pot

The surface of the corroded or rusted zinc pot will become quite rough, which will cause more serious corrosion of liquid zinc. Therefore, if the new zinc pot needs to be stored for a long period of time before use, anti-corrosion protection measures should be taken, including painting protection, putting it in the workshop or covering to avoid rain, padding the bottom to avoid soaking in water, etc. Under no circumstances should water vapor or water accumulate on the zinc pot.

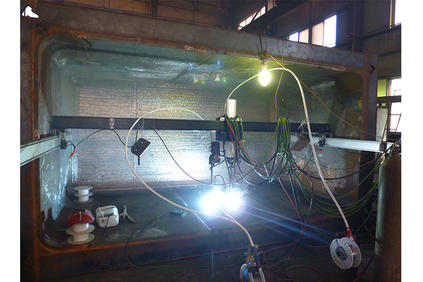

2. Installation of zinc pot

When installing the zinc pot, it must be moved into the zinc furnace according to the requirements of the manufacturer. Before using a new boiler, be sure to remove the rust, residual welding slag spatter and other dirt and corrosives on the boiler wall. Rust shall be removed by mechanical method, but the surface of the zinc pot shall not be damaged or rough. A hard synthetic fiber brush can be used for cleaning.

The zinc pot will expand when heated, so there should be room for free expansion. In addition, when the zinc pot is in high temperature for a long time, "creep" will occur. Therefore, proper supporting structure shall be adopted for the zinc pot during design to prevent it from gradually deforming during use.